Thermador HPIB42HS Installation Instructions - Page 7

Circulating-air mode, For optimum hood efficiency, CONNECTING A, EXHAUST-AIR, Step 2: PREPARING

|

View all Thermador HPIB42HS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

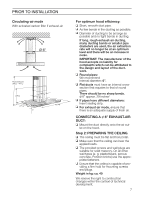

PRIOR TO INSTALLATION Circulating-air mode With activated carbon filter if exhaust-air Ø 6" Recirculating-air 305/8" - 421/4" 235/8" 271/2" 3" 42"/48" For optimum hood efficiency: K Short, smooth duct pipe. K As few bends in the ducting as possible. K Diameter of ducting to be as large as possible and no tight bends in ducting. If long, rough exhaust-air ducting, many ducting bends or smaller pipe diameters are used, the air extraction rate will no longer be at an optimum level and there will be an increase in noise. IMPORTANT: The manufacturer of the hood accepts no liability for complaints which can be attributed to the design and layout of the ductwork. K Round pipes: We recommend Internal diameter: 6". K Flat ducts must have an internal crosssection that equates to that of round pipes. There should be no sharp bends. l 6" approx. 29 inches2 K If pipes have different diameters: Insert sealing strip. K For exhaust-air mode, ensure that there is an adequate supply of fresh air. CONNECTING A l 6" EXHAUST-AIR DUCT: K Mount the duct directly onto the air outlet on the hood. Step 2: PREPARING THE CEILING K The ceiling must be flat and horizontal. K Make sure that the ceiling can bear the applied loads. K The provided screws and wall plugs are suitable for solid masonry. On all other wall types (e. g. plasterboard, porous concrete, Poroton bricks) use the appropriate fasteners. K Ensure that the ceiling is capable of providing a firm hold for mounting screws and plugs. Weight in kg: ca. 49 We reserve the right to construction changes within the context of technical development. 7