Brother International HE-800B Instruction Manual - English - Page 76

Adjusting the cutter installation, happens, replace or sharpen the cutter.

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 76 highlights

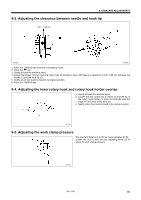

9. STANDARD ADJUSTMENTS 9-6. Adjusting the cutter installation Lowest position Top of needle plate Lowest position 1. Install the cutter with the screw (1) so that the tip A of the cutter blade is aligned with the top of the needle plate when the cutter is pressed down by hand to its lowest position. * If using the flat cutter (2), install with the screw (1) so that there is a clearance of 1.5-2.0 mm between the cutter and the top of the needle plate. NOTE: ・ When the cutter is driven by the solenoid, the movement will be approximately 2 mm greater than that shown in the illustration. ・ If the cutter does not cut properly, the cutter may get stuck in the material and not return. If this happens, replace or sharpen the cutter. Top of needle plate 1.5 - 2.0 mm 3979Q 2. Loosen the two screws (4), and move the cutter holder (5) to adjust so that the clearance between the cutter and the needle bar (3) is 0.3 mm. * Check that the needle bar (3) does not touch the cutter when it moves sideways. 0.3 mm 3980Q 67 HE-800B