Brother International HE-800B Instruction Manual - English - Page 82

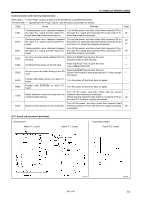

TABLE OF ERROR CODES, Feed mechanism-related errors, Work clamp-related errors, Turn off the power

|

View all Brother International HE-800B manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 82 highlights

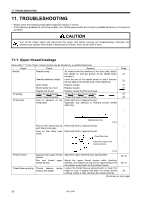

10. TABLE OF ERROR CODES Code E132 E133 E150 Cause Remedy Page Problem detected with upper shaft motor operation. Turn off the power, and then check that synchronizer connector P11 on the motor P.C. board is properly connected. 11* Upper shaft motor stopping position is incorrect. (During automatic needle lifting) Turn off the power, and then check that synchronizer connector P11 on the motor P.C. board is properly connected. 11* Upper shaft motor is overheating, or temperature sensor is faulty. Turn off the power, and then check the upper shaft motor. * Feed mechanism-related errors Items with a "*" in the "Page" column should only be handled by a qualified technician. Code Cause Remedy Page E200 Needle zigzag motor home position cannot be detected. Needle zigzag motor, needle zigzag sensor or needle zigzag encoder signal is not connected correctly. Turn off the power, and then check that the needle zigzag sensor and needle zigzag encoder connector P17 and the needle zigzag motor connector P21 on the main P.C. board are properly connected. 10* E201 Needle zigzag motor stopped due to a Turn off the power, and then check if there are any problem. problems in the needle zigzag direction. * E210 Feed motor home position cannot be Turn off the power, and then check that the feed sensor detected. connector P8, feed encoder connector P18 and feed Feed motor, feed sensor or feed encoder motor connector P22 on the main P.C. board are properly 10* signal is not connected correctly. connected. E211 Feed motor stopped due to a problem. Turn off the power, and then check if there are any problems in the feed direction. * Work clamp-related errors Items with a "*" in the "Page" column should only be handled by a qualified technician. Code E300 E301 Cause Work clamp motor home position cannot be detected. Work clamp motor, work clamp sensor or work clamp encoder signal is not connected correctly. Work clamp motor stopped due to a problem. Remedy Turn off the power, and then check that the work clamp sensor and work clamp encoder connector P19 and the work clamp motor connector P23 on the main P.C. board are properly connected. Turn off the power, and then move the work clamp up and down and check that it moves smoothly. Page 10* * 73 HE-800B