Brother International RH-9820 Instruction Manual - English - Page 86

Adjusting the looper stroke, Tilt back the machine head.

|

View all Brother International RH-9820 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 86 highlights

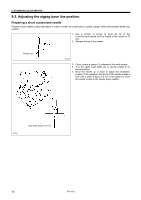

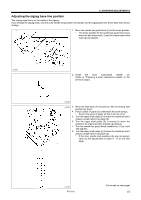

9. STANDARD ADJUSTMENTS 9-5. Adjusting the looper stroke The standard looper stroke is 2.7 mm. (It may be preferable to change this depending on the material and thread.) * Carry out the adjustment in "9-4. Adjusting the needle and looper timing" before making this adjustment. 0489B 1. Turn the upper shaft pulley (1) to set the needle bar to the needle drop position at the inside sewing position. 2. At this position, use calipers to measure the length from the edge of the needle bar (2) to the top of the needle bar bush holder base (3). 3. Add 2.7 mm to the value obtained in step 2 above, and set the width of the calipers to the resulting value. 4. Turn the upper shaft pulley (1) until the edge of the needle bar (2) touches the edge of the calipers, and stop turning the upper shaft pulley (1) at that point (A). Moves to left Moves to right 0490B Push against Should be no gap 0327B 0491B 5. Tilt back the machine head. 6. Loosen the two set screws (5) of the lower shaft cam (4). 7. With the upper shaft pulley (1) stopped, turn the lower shaft cam (4) to adjust so that the tip of the eye looper (6) is aligned with the needle center (7). 8. Once adjustment is complete, push the lower shaft cam (4) against the surface of the bearing collar (8), and then securely tighten the two set screws (5). 77 RH-9820