Craftsman 17540 Operation Manual - Page 19

DEPTH-STOP, RODANDDEPTH-STOP, TURRET, 7andS, TheDepth-Stop, Rodand, theDepth-Stop, Turret, areused,

|

View all Craftsman 17540 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

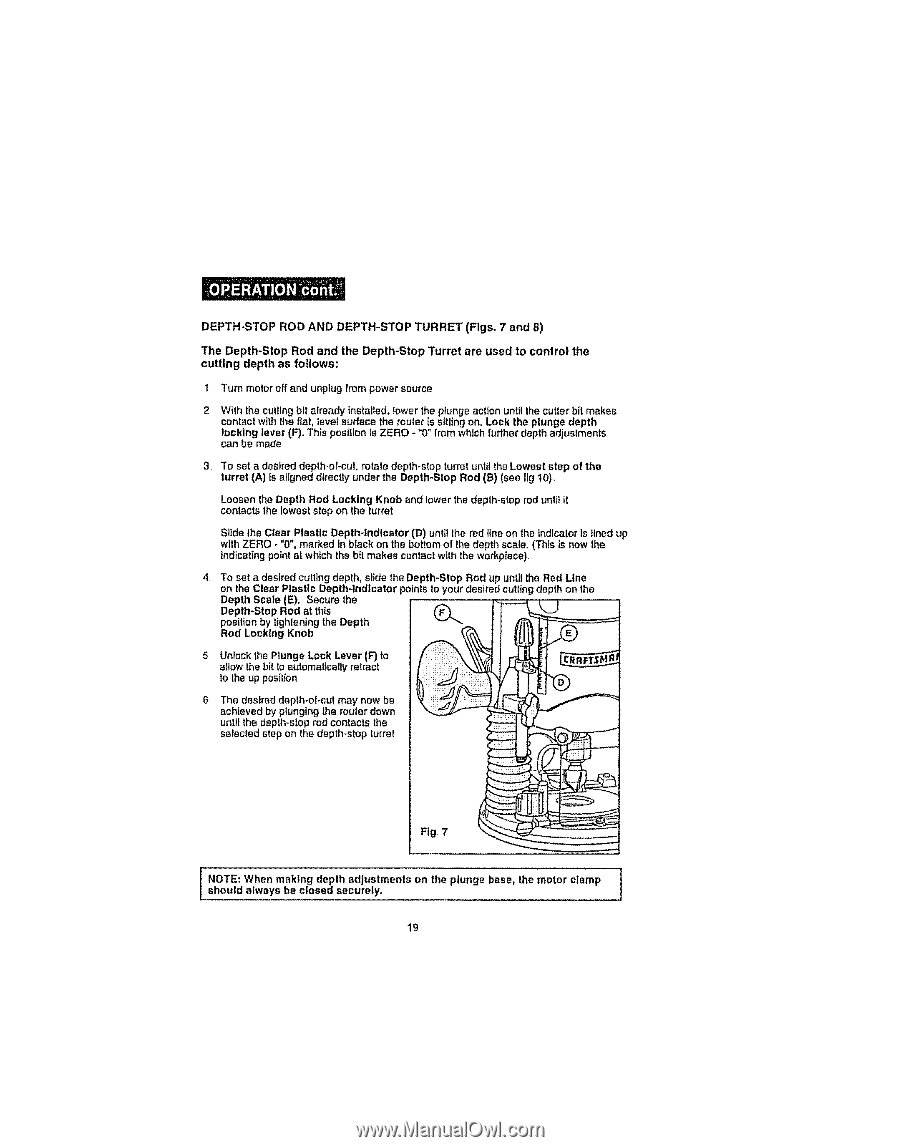

DEPTH-STROOPDANDDEPTH-STTOUPRRE(FTigs7,,andS) TheDepth-StRopodandtheDepth-StTouprreatreusedtocontrothl e cuttingdepthasfollows: t Turn motor off and unplug from power source 2 With the cutting bit already installed,Iowar the plunge action until the cutter bit makes contact with the f_at,level surface the router is sitting on, Lock the plunge depth locking lever (F}oThis position is ZERO - "0" lrom which furtherdepth adjustments can be made 3 To set a desired depth-el-cut, rotate depth-stop turret until theLowest step of the turret (A) is aligned dlreegy under the Depth*Stop Rod (B) (see I]g 10), Loosen the Depth Rod Locking Knob and lower the depth-stop rod until it contactsthe lowest step on the turret Slide the Clear Plastic Depth-tndlcstor (D) until the red line on the indicator is lined up with ZERO - "0", marked in black on the bottom of the depth scale, (Thls is now the indicating point at which the bit makes contact wi|h the workpiece) To set a desired cutting depth, slide the Depth-Stop Rod up until lhe Red Line on the Clear Plastic Depth-indicator points to your desired curling dep|h on Ihe Depth Scale (E), Secure the Depth-Stop Rod st thls (_ position by tighleniog the Depth Rod Locking Knob 5 Unlock the Plunge Lock Lever (F) to allow the bit to automatically retract to the up position The desired depth-of-cut may now be achieved by plunging the router down unltt the depth-stop rod conlacts the selected step en the depth-stop turret Fig- 7 "1 ! sNhOoTuEld,' Walhweanysmabkeincg!osdeedptshecaudrjueslyt.ments on the plunge base_ the motor clamp | 19