Cub Cadet Z-Force 48 Z-Force 48 Operator's Manual - Page 23

Oil Chart, Lubrication Chart - mower blades

|

View all Cub Cadet Z-Force 48 manuals

Add to My Manuals

Save this manual to your list of manuals |

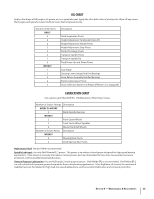

Page 23 highlights

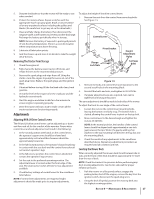

OIL CHART Apply a few drops of SAE engine oil, grease, or use a spray lubricant. Apply the oil to both sides of pivot points. Wipe off any excess. Start engine and operate mower briefly to insure that oil spreads evenly. Number of Oil Points DAILY 4 4 2 2 2 2 1 2 WEEKLY 1 2 2 2 2 Description Deck Suspension Pivots Height Adjustment Turnbuckle Clevis Pin Height Adjustment Handle Pivots Height Adjustment Stop Pivots Deck Lift Linkage Pivots Transport Handle Pivots Transport Handle Pin Deck Frame Up-and-Down Pivots Seat Hinge Steering Lever Linkage Rod End Bearings Lever Return Assembly Rod End Bearings Pump Control Lever Pivots Grass Collection System Lid Hinges (If Mower is so equipped) LUBRICATION CHART Use a grease-gun filled with NO. 2 Multipurpose Lithium Base Grease Number of Grease Fittings Description EVERY 25 HOURS 3 Blade Spindle Bearings WEEKLY 2 Front Caster Wheels 2 Front Caster Wheel Spindles 2 Mower Deck Ball Wheels Number of Grease Points Description WEEKLY 4 Mowing Deck Pivots 2 Deck Take-Up Idler Pivots Hydrostatic Fluid: Rimula 15W40 recommended. Spindle Lubricant: Use only Shell Alvania RL 2 grease. This grease is an amber-colored grease designed for high speed bearing applications. It has a base oil viscosity that reduces running losses, has been formulated for low noise, has excellent corrosion protection, and has excellent bearing lubrication. General Purpose Lubrication: Use any NLGI grade 2 multi-purpose grease. Shell Albida EP2 is recommended. Shell Albida EP 2 is a red-colored multi-purpose grease designed for heavy-duty bearing applications. It has high base oil viscosity for mechanical stability, has been formulated for high load, low-speed applications, and has excellent lubrication and corrosion protection. Section 6 - Maintenance & Adjustments 23