Epson 680Pro Service Manual - Page 52

EPSON Stylus COLOR 680/777/777i, Revision B, Troubleshooting

|

UPC - 010343832138

View all Epson 680Pro manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 52 highlights

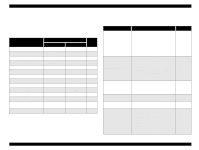

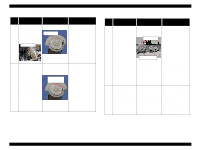

EPSON Stylus COLOR 680/777/777i Table 3-4. Error Condition and possible cause (continued) Symptom Possible Cause Check table Any error indication is not displayed. But, the paper is not ejected completely. Paper jam dose not occur. • Paper eject roller gear is disengaged from the pump's gears. • The Paper eject frame is not assembled in the Paper eject frame. Figure 3-17 Dot missing occur and it is not recovered with CL Print quality is not good • Vertical banding • Horizontal banding • Printing is blurred • Ink stains the paper • Pump unit dose not absorb the ink from the printhead. • Cap unit dose not stick on the surface of the printhead completely. • The printhead is broken. • The head FFC has any damage. • The main board is defective. • The accuracy of the CR motor is lowered. • The lack of the lubricant around the CR unit. • The both I/C is not held in the CR unit securely. • The Paper eject frame is deformed. • Any foreign material is sticking around the printhead. • Paper feed accuracy is lowered. • Printer driver setting is not suitable. • Paper path has ink stain somewhere. Figure 3-18 Figure 3-19 Figure 3-20 Table 3-21 Table 3-22 Table 3-23 Revision B If the problem fits to the detail phenomenon in the table, make sure the check point and repair the product following the corresponding remedy mentioned in the table when you find the defective parts in the check point. Table 3-5. Paper out error indication Step No. 1 Detail phenomenon Check point • Check the surface of the LD roller if the micro pearl or severe smear is adhered. ASF LD roller attempt to load the paper. But, paper is not loaded at all. The LD roller seems slipping. LD roller If it is no problem, proceed the next step. Remedy • Set a cleaning sheet in the ASF up side down. Then holding the top edge, try to load the paper from the Printer driver. The micro pearl on the LD roller surface is removed. To remove severe smear, staple a cloth moistened with alcohol to a post card and clean the roller in the same manner. N o n - a d h e s iv e A r e a C L S heet A d h e s iv e A r e a T h is s id e d o w n (U s e a p o s t c a rd fo r th e b a s e s h e e t.) S ta p le r s C lo th m o is te n e d w ith a lc o h o l • If the problem is not solved, replace the LD roller with new one. Troubleshooting Troubleshooting with LED Error Indications 52