Haier HC60D1VAR User Manual - Page 16

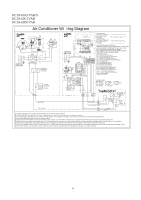

Air Conditioner Wi, ring Diagram

|

View all Haier HC60D1VAR manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

HC18-60A1VAR/S HC18-60C1VAR HC18-60D1VAR Air Conditioner Wi ri ng Diagram 5 YL 6C S R RD BK RD OFM 6 M BR R S BR BK PU L1 BK L2 WH GND 208/230V 60Hz 1PH CC 4 RD PU BL YL P3 P2 P1 Compress or Prot ect 3 Min. Time Delay BL BL YL LPS 2 HPS YL Opt ional Low & High Pressur e Switches YL CY COMPRESSOR 24VAC COMMON OPTIONAL ELECTRIC HEATER KIT BRK L1 BK FL BK BK FL BK RD RD RD TL L2 RD BK RD RD TL RD 208/230V 60Hz 1PH PU BL BR WH 1 234 56 L1 BK L2 WH GND IBM M BR S R GR BR PU BCAP BCR 1 NC 2 3 NO 4 5 COM 6 7 8 BL GR 7 1 234 5 6 1 234 5 6 BK RD PU BL BR WH BK- HI 3 BK RD-LO BK L1 RD L2 RD OR TRAN 230 208 COM RD BL LINE VOLTA GE FACTORY STANDA RD FIELD INSTALLED OPTIONAL LOW VOLT AGE FACTORY STANDA RD FIELD INSTALLED OPTIONAL USE COPPER CONDUCTORS ONLY WARNING CABI NET MUST BE PERMANENTLY GROUNDED AND ALL WIRING TO CONFORM TO I.E.C.,N.E.C.,C.E.C., C.L.C. AND LOCAL CODES AS APPLICAB LE. REPLACEMENT WIRE MUST BE THE SAME GAGE AND INSULATION TYPE AS ORIGINAL WIRE. COMPONENT CODES BCR - BLOWER CONTROL RELA Y BCAP - RUN CAPACITOR BLOWER MOTOR CC - COMPRESSOR CONTACT OR CCH - CRANKCASE HEATER ( OPTIONAL) CHS - CRANKCAS E HEATER SWITCH (OPTIONAL) CMPR - COMPRESSOR HPS - HIGH PRESSURE SWITCH LPS - LOW PRESSURE SWITCH IBM - INDOOR BLO WER MOTOR OFM - OUTDOOR FAN MOTOR RCAP - RUN CAPA CITOR COMPRESSOR RVS - REVERSING VALVE S OLENOID STCAP - START CAPA CITOR (OPTIONAL) STRLY - START RELA Y (OPTIONAL) STRTH - START THERMISTOR (OPTIONAL) TRAN - TRANSFORMER 230/208 SELECTA BLE COLOR CODES BK - BLACK BL - BLUE GY - GRAY BR - BROWN GR- GREEN OR - ORANGE PU - PURPLE RD - RED VI - VIOLET WH - WHITE YL - YELLOW SW-1 BL RD BL BL RC G BR WH W2 W RESISTANCE Y HEAT CONTROL W G INDOOR FAN CONTROL R C RHS-1 FAN HA CA AUTO TS ON RHS-2 HEAT OFF COOL HEAT OFF COOL LED SW-2 1) Confi rm sy stem selec tion. Opti onal com ponents m ay be field or factory installed. 2) If LPS and/or HPS not in stalled or removed, a ju mper wire must be present acr oss circu it for syst em to operate. 3) For pr oper syste m oper ation, consul t indo or uni t and outdoor unit installat ion inst ructi ons to con firm syst em mat ch up and blower spe ed sel ect io n. 4) Alt ernat e double pole contac tor us ed on some syst ems. 5) Onl y one sta rt assist method to be u sed at a ti me, consul t outdoo r un it inst all ati on instr ucti ons for app lication information. Use only f act ory appr oved accesso ries. 6) Opti onal OFM com ponents m ay connect capac itor com mon and mo tor com mon, for r ecipr ocati ng compres sor ther e may have cran kcase heat er co nsu lt ou tdoor u nit inst allat ion inst ruct ions for d etails.Select the run ning capa cit or(one or dua l)and connect.If IFM or OFM only have on e capacit or wire,co nnec t Com wire t o cap acitor. 7) Indoor uni t s hipped w ithout optional electr ic heater ki t. To inst all opt ional heat er ki t,remove po wer pi g tail up to 9 pin plug. Inst all heater kit and con nect with mating 9 pin plu g. Run syst em power connect ions di rect ly to elect ric h eater kit pow er terminals. Consult heat er ki t inst allation instructions for complete det ails. 14