Hitachi G23SR Instruction Manual - Page 15

Maintenance And Inspection - brushes

|

View all Hitachi G23SR manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

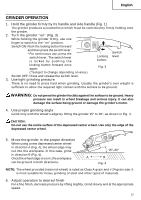

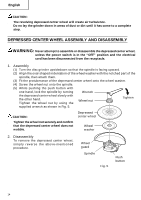

English MAINTENANCE AND INSPECTION WARNING: Be sure to switch power OFF and disconnect the plug from the receptacle during maintenance and inspection. Using cracked, deformed or damaged wheels can lead to wheel breakage and resulting serious injury. 1. Replacing the depressed center wheel Replace the depressed center wheel when it has been worn out to about 2-3/8" (60mm) in external diameter. Confirm that there is no crack or any damage to the depressed center wheel. If there is a crack or a transformation in the wheel, replace it immediately. 2. Inspecting the screws Regularly inspect all screws and ensure that they are fully tightened. Should any of the screws be loosened, retighten them immediately. WARNING: Using this grinder with loosened screws is extremely dangerous. 3. Confirm that there is no damage in the wheel guard, the electrical cord and the housing, etc. Check that the on/off switch operates normally. 4. Inspecting the carbon brushes (Fig. 6) The Motor employs carbon brushes which are consumable parts. When they become worn to or near the "wear limit", it could result in motor trouble. When an auto-stop carbon brush is equipped, the motor will stop automatically. At that time, replace both carbon brushes with new ones which have the same carbon brush Numbers shown in the figure. In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders. CAUTION: Using this grinder with a carbon brush which is worn in excess of the wear limit will damage the motor. Wear limit a 0.67" (17 mm) No. of carbon brush Fig. 6 Usual carbon brush Auto-stop carbon brush a 0.24" (6 mm) 0.28" (7 mm) No. of carbon brush 44 74 NOTE: Use HITACHI carbon brush No. 44 or 74 indicated in Fig. 6. 15