Hitachi HDS722512VLAT20 Product Brief - Page 5

excessive motion or vibration during

|

View all Hitachi HDS722512VLAT20 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

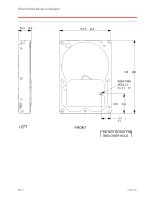

Hitachi Global Storage Technologies definitions upon the deassertion of DMACK- at the termination of the DMA burst. See the table below. Ultra DMA definitions Special definition (for Ultra DMA) DDMARDY- Write HSTROBE STOP HDMARDY - Read DSTROBE STOP Conventional definition IORDY DIOR- DIOW- DIOR- IORDY DIOW- Mechanical data Height Width Length 25.4 mm ± 0.4 101.6 mm ± 0.4 146.0 mm ± 0.6 Weight (maximum) 640 grams Mounting The drive will operate in all axes (six directions). Performance and error rate will stay within specification limits if the drive is operated in the other permissible orientations from which it was formatted. For reliable operation the drive must be mounted in the system securely enough to prevent damage from excessive motion or vibration during seek operation or spindle rotation, using appropriate screws or equivalent mounting hardware. Drive level vibration test and shock test are to be conducted with the drive mounted to the table using the bottom four screws. Mounting holes Dimension reference number Dimension (mm) (1) (2) (3) 41.28 ± 0.5 44.45 ± 0.2 95.25 ± 0.2 (4) 6.35 ± 0.2 (5) 28.5 ± 0.5 (6) 60.0 ± 0.2 Mounting screw thread count = 6-32 UNC Notes: Recommended screw torque to be applied to mounting screws is 0.6-1.0 Nm (6-10 kg-cm). (7) 41.6 ± 0.2 Page 5 version 1.0