LG GR-K18PBS Service Manual - Page 40

LG GR-K18PBS Manual

|

View all LG GR-K18PBS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

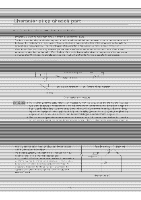

Item -5. Charging the refrigerant Evaporator Compressor '' Drier Condenser High pressure 3-Way side Valve Hot Line Pipe 4) Charging the refrigerant: As shown above, operate the refrigerant-with the charging pipe. -5) When-lhe-charging is complete, pinch the charging pipe using the pinch-off oiler. 6) After welding the end of the pinched charging pipe with copper, test for gas leakage on the welding part. _6_ Testing for gas leakage ___LIsingan electric weight, test for leakage on welded parts and other errs than you think can leak gas out. 7 Arranging cycle piping each part men me work is done, check whether all pipes are in its original position before closing- the cover back-M/C. Especially maintain a distance (10mm) between the pipes so that it_ does not touch each other. 1) Fulluw safety principles of handling gas. 2) Use a plate jig (or wet towel), if needed,-to prevent-any skin burn from wires during welding. (to damaged, to prevent safety accidents and to ensuteimeduct safety ) 3) Prevent pipe copper pipe oxidization from overheating dining welding. 1) Follow the insertion length of tho capillary tubo to tho drivor of 13 :0 MOLECULAI -SIEVES N DRIER el t Cuttiilg u.e . ipillary tubermake-Sbreritd098710tgetCrUStied 6) When doing the welding, make sure the suction tube does not be mixed with the charging tube. (High efficiency pump)