Lexmark E250D Service Manual - Page 53

Messages and error codes, User attendance messages, Paper jam error codes - user manual

|

View all Lexmark E250D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 53 highlights

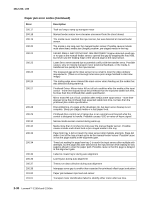

4512-220, -230 Messages and error codes Note: The following message and error codes will be visible only in the print history in the diagnostic mode for E250d and E250dn. See "Diagnostics mode selections" on page 3-8. The printer operator panel displays light patterns describing the current state of the printer and indicates possible printer problems that must be resolved. This topic provides a list of all printer messages and explains what they mean. User attendance messages Cartridge error codes Error 31 32 33 Description Defective cartridge Unsupported cartridge Invalid refill Paper jam error codes Paper jam error codes Error 200.00 200.01 200.02 200.03 200.04 200.06 200.08 200.09 200.12 200.13 200.14 200.15 200.16 Description Paper jam around input sensor. Classic input jam. The media is too long over the input sensor. Possible causes include multi-sheet feed, tray size sensing problem, and media slippage. The main input sensor never became uncovered from the sheet ahead. The video never started on the page at the input sensor within two inches after hitting the input sensor The media at the input sensor before interrupt occurred - not enough time elapsed since the printhead started to expect the printhead mirror motor lock. Possible causes include bouncy sensor or exceptionally fast pick - perhaps due to media pre-staged in the source tray. Imaged page not expected page (bouncy passthru sensor) Media reached the input sensor before the EP was ready Transfer servo never started Media detected at manual feeder sensor when not expected. Possible causes include user insert of media when motor is running or pre-staged media in the tray. The input sensor is covered when the media is not expected (media in machine during warm-up) Trailing edge cleared manual feed, but did not successfully debounce the sensor. Potential causes are a small gap or a bouncy manual feed sensor. UNRECOVERABLE NO GAP JAM. Engine detected no gap at the manual feeder sensor, attempted to open the gap by stopping the feed rolls, but no trailing edge was ever seen at the input sensor. Transport motor error detected Diagnostic information 2-29