Lexmark E250D Service Manual - Page 55

-230, Error, Description, Duplex jam while staging in the device - restart

|

View all Lexmark E250D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 55 highlights

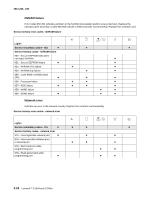

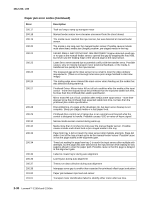

4512-220, -230 Paper jam error codes (Continued) Error 201.02 201.03 201.05 201.25 201.26 201.27 202.00 202.01 202.02 202.06 202.13 202.25 202.26 202.32 231.00 231.01 231.02 232.00 232.01 232.02 233.00 233.01 233.02 233.03 234.01 235.01 241.00 Description Exit sensor never made by leading edge of page. Also known as internal jam. Video never started on the page at the input sensor within two inches after hitting the input sensor Restart attempted after an internal jam without the cover open/close event. It is likely that the jam was never cleared. Exit sensor never made by leading edge of media when feeding out the media that was detected during warm-up. Page at fuser nip before fuser started ramping toward desired temperature. Indicates code may be receiving more hall interrupts than intended Page at fuser nip before fuser reached acceptable operating temperature. Page arrived at fuser earlier than expected, so it was probably staged Paper jam around exit sensor. Exit sensor never broke on the trailing edge of the sheet at the exit sensor. Exit sensor never broke from sheet ahead of page heading toward the exit sensor. Exit sensor bounced Exit sensor covered, media not expected (media not in machine during warm-up) Exit sensor never broke from the sheet ahead of the page heading toward the exit sensor when feeding out the media detected during warm-up. Trailing edge never cleared exit sensor when feeding out media that was detected during warm-up. Long media or shingled multi feed stopped before sending to duplex. Duplex jam while reversing into the device Duplex sensor never made by leading edge reversing into the duplex. x1=sensor state Bouncy duplex sensor never made. x1+x2=paper path location Duplex jam while staging in the device Duplex sensor never broke by the sheet ahead after reversing into the duplex. x1=sensor state, x2+x3=paper path location Page in duplex ahead of current reversing page never staged. x1=duplex sensor state (1=made), x2+x3=paper path location Duplex jam while picking from the device Page in duplex never picked. x1+x2=paper path location Feed error picking from the duplex. x1=source, x2+x3=time since pick Paper never reached the input sensor, but was detected at the manual feed sensor. Duplex sensor covered during warm-up. Invalid duplex media Paper jam near tray 1. Diagnostic information 2-31