Lexmark MC2640 Paper and Specialty Media Guide PDF - Page 13

Selecting preprinted forms and letterhead, Smoothness, Moisture content, Grain direction

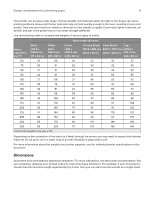

|

View all Lexmark MC2640 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

Guidelines for selecting and using paper 13 Smoothness Paper smoothness directly affects print quality. If paper is too rough, toner cannot fuse to it properly. If paper is too smooth, it can cause paper feeding or print quality issues. We recommend the use of paper with 50 Sheffield points for color laser printers and 150-250 Sheffield points for mono laser printers. Moisture content The amount of moisture in paper affects both print quality and the printer ability to feed the paper correctly. Leave paper in its original wrapper until you use it. Exposure of paper to moisture changes can degrade its performance. Store paper in its original wrapper in the same environment as the printer for 24 to 48 hours before printing. Extend the time several days if the storage or transportation environment is very different from the printer environment. Thick paper may also require a longer conditioning period. Grain direction Grain refers to the alignment of the paper fibers in a sheet of paper. Grain is either grain long, running the length of the paper, or grain short, running the width of the paper. For 60-176 g/m2 (16-47‑lb) paper, grain long paper is recommended. Fiber content Most high‑quality xerographic paper is made from 100 percent chemically treated pulped wood. This content provides the paper with a high degree of stability, resulting in fewer paper feeding problems and better print quality. Paper containing fibers such as cotton can negatively affect paper handling. Selecting preprinted forms and letterhead • Use grain long paper. • Use only forms and letterhead printed using an offset lithographic or engraved printing process. • Avoid paper with rough or heavily textured surfaces. • Use inks that are not affected by the resin in toner. Inks that are oxidation‑set or oil‑based generally meet these requirements; latex inks might not. • Print samples on preprinted forms and letterheads considered for use before buying large quantities. This action determines whether the ink in the preprinted form or letterhead affects print quality. • When in doubt, contact your paper supplier. • When printing on letterhead, load the paper in the proper orientation for your printer. For more information, see "Printer-specific paper support" on page 30.