Lexmark MC2640 Paper and Specialty Media Guide PDF - Page 24

Printing on labels, Maintenance procedures, Integrated forms

|

View all Lexmark MC2640 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

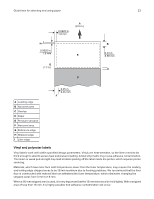

Guidelines for selecting and using paper 24 Vinyls are non‑absorbing, which leads to toner buildup in the fuser that requires special maintenance. For more information about maintaining your printer, see the documentation that came with your printer. Vinyls may require a topcoat to ensure good toner adhesion. When you run vinyl labels, you may be required to install an oil fuser cleaner. Polyester labels are less heat‑sensitive but are also non‑absorbing. Backings for polyester labels can be thinner, but requirements for coatings and cleaning are similar to vinyl labels. Integrated forms To create integrated forms, the converter uses hot melt adhesives to apply the label adhesive and liner to a base material (generally paper). Oil bleed, recognizable by a discolored face sheet, can be a problem with these forms. Oil may also migrate from the top to the back surface of the liner while it is on the roll, before the conversion process takes place. The forms may be slick, and the pick mechanism of your printer may be unable to move all the sheets from the tray into the printer. Jamming and misfeeds increase when oil is present on the back of the liner. The adhesive on these forms is commonly patterned on two or four sides (a non‑adhesive border on either two or four edges). We recommend designing a 1‑mm (0.04‑in.) non‑adhesive border (zone coated) on all four edges. When printing on integrated forms with a grain long base material, position the form in the tray so the paper portion of the form feeds into the printer first. Position the pressure‑sensitive portion of the form toward the portrait left edge. For integrated forms with a grain short base material, position the form in the tray so the pressure‑sensitive portion feeds into the printer first. Due to the unique construction of integrated forms, you may experience stacking problems in the output bin. If you experience stacking problems with these forms, then contact your marketing representative. Note: Test some forms before purchasing large quantities. Printing on labels Print on full label sheets only. Sheets with missing labels could peel off during printing and result in a paper jam. Partial sheets can also leave adhesive marks on the printer and cartridge, which could void the printer and cartridge service warranties. Do not feed labels through the printer more than once. Doing so may contaminate the cartridge and other components with adhesive. Depending on your printer model and the number of labels being printed, printing labels may require special printer maintenance. For more information about printing on labels, see "Printer-specific paper support" on page 30. Maintenance procedures Note: These procedures apply only to mono laser printers. If print quality begins to degrade when printing on vinyl labels, then do the following: 1 Print on five sheets of paper. 2 Wait approximately five seconds. 3 Print on five more sheets of paper. To maintain printer feeding reliability, repeat this cleaning process every time you replace the toner cartridge.