Makita JR3070CT Owners Manual - Page 6

Operation, Maintenance - vibration

|

View all Makita JR3070CT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

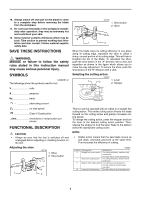

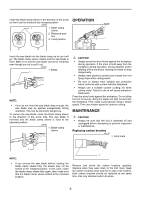

rotate the blade clamp sleeve in the direction of the arrow so that it can be locked at the released positon. 005787 1 1. Blade clamp sleeve 2. Released posi- tion 3. Fixed position OPERATION 006186 2 3 Insert the saw blade into the blade clamp as far as it will go. The blade clamp sleeve rotates and the saw blade is fixed. Make sure that the saw blade cannot be extracted even though you try to pull it out. 005788 1. Blade 1 NOTE: • If you do not insert the saw blade deep enough, the saw blade may be ejected unexpectedly during operation. This can be extremely dangerous. To remove the saw blade, rotate the blade clamp sleeve in the direction of the arrow fully. The saw blade is removed and the blade clamp sleeve is fixed at the released position. 005789 1. Blade clamp sleeve CAUTION: • Always press the shoe firmly against the workpiece during operation. If the shoe is held away from the workpiece during operation, strong vibration and/or twisting will be produced, causing the blade to snap dangerously. • Always wear gloves to protect your hands from hot flying chips when cutting metal. • Be sure to always wear suitable eye protection which conforms with current national standards. • Always use a suitable coolant (cutting oil) when cutting metal. Failure to do so will cause premature blade wear. Press the shoe firmly against the workpiece. Do not allow the tool to bounce. Bring the blade into light contact with the workpiece. First, make a pilot groove using a slower speed. Then use a faster speed to continue cutting. MAINTENANCE CAUTION: • Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance. Replacing carbon brushes 001145 1. Limit mark 1 NOTE: • If you remove the saw blade without rotating the blade clamp sleeve fully, the sleeve may not be locked of the released positon. In this case, rotate the blade clamp sleeve fully again, then make sure that the blade clamp sleeve locked at the released position. 1 Remove and check the carbon brushes regularly. Replace when they wear down to the limit mark. Keep the carbon brushes clean and free to slip in the holders. Both carbon brushes should be replaced at the same time. Use only identical carbon brushes. 6