Oreck XL2800H2 Owners Guide - Page 6

How to Replace a Worn Belt To Adjust or Replace Brush - base plate

|

View all Oreck XL2800H2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

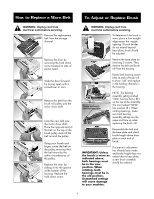

How to Replace a Worn Belt To Adjust or Replace Brush WARNING: Unplug cord from electrical outlet before servicing. Remove the replacement belt from the storage channel. Remove the door by removing the hold down screw located on side of power head. Slide the door forward by prying open with a screwdriver or coin. Remove the belt from the brush roll pulley and the motor drive shaft. Loop the new belt over the motor drive shaft. Place the opposite end of the belt on the top of the brush pulley and roll the belt around the pulley. Using your thumb and finger, rotate the belt on the pulley, ensuring that the belt encircles the entire circumference of the pulley. Replace the door by sliding it into the groove at the bottom of the housing. Replace the hold down screw. WARNING: Unplug cord from electrical outlet before servicing. To determine if the brush is worn, place a firm straight edge across the nozzle opening. If brush bristles do not extend beyond base plate, brush should be adjusted. Remove the base plate by removing 5 screws. Then, remove the belt and brush roll from the housing. Rotate both bearing assemblies at ends of brush roll to show "old" and replace in the holding channels in the housing. Rotate and match bearing assemblies NOTE: The bearing assembly setting marked "OLD" has two bars ( l l ) on the top of the assembly. The one marked "NEW" has one bar ( l ). When rotating bearings, make sure both bearing assembly settings are the same and face up when replacing the brush roll. Reassemble the belt and the base plate and check bristle height above base plate at each end of brush. IMPORTANT: Unless the brush is worn as indicated above, both bearings must be in the new position. When rotating, both bearings must be in the old position. Unmatched settings will cause damage to your machine. If a previous adjustment has already been made and bristle height does not extend above base plate, a new brush assembly should be ordered. 6