Brother International PC-7000 Users Manual - English - Page 112

Troubleshooting

|

View all Brother International PC-7000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 112 highlights

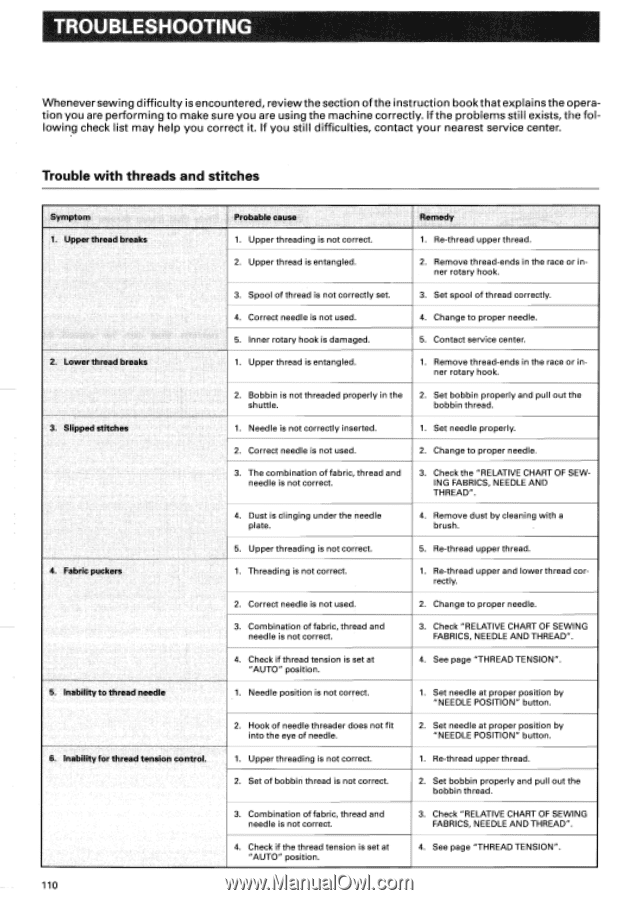

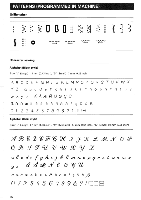

TROUBLESHOOTING Whenever sewing difficulty is encountered, review the section of the instruction book that explains the operation you are performing to make sure you are using the machine correctly. if the problems still exists, the following check list may help you correct it. If you still difficulties, contact your nearest service center. Trouble with threads and stitches Symptom 1. Upper thread breaks 2. Lower thread breaks 3. Slipped stitches 4. Fabric puckers 5. Inability to thread needle 6. Inability for thread tension control. 110 Probable cause Remedy 1. Upper threading is not correct. 1. Re-thread upper thread. 2. Upper thread is entangled. 2. Remove thread-ends in the race or inner rotary hook. 3. Spool of thread is not correctly set. 3. Set spool of thread correctly. 4. Correct needle is not used. 4. Change to proper needle. 5. Inner rotary hook is damaged. 5. Contact service center. 1. Upper thread is entangled. 1. Remove thread-ends in the race or inner rotary hook. 2. Bobbin is not threaded properly in the 2. Set bobbin properly and pull out the shuttle. bobbin thread. 1. Needle is not correctly inserted. 1. Set needle properly. 2. Correct needle is not used. 2. Change to proper needle. 3. The combination of fabric, thread and needle is not correct. 3. Check the "RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD". 4. Dust is clinging under the needle plate. 4. Remove dust by cleaning with a brush. 5. Upper threading is not correct. 5. Re-thread upper thread. 1. Threading is not correct. 1. Re-thread upper and lower thread correctly. 2. Correct needle is not used. 2. Change to proper needle. 3. Combination of fabric, thread and needle is not correct. 3. Check "RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD". 4. Check if thread tension is set at "AUTO" position. 4. See page "THREAD TENSION". 1. Needle position is not correct. 1. Set needle at proper position by "NEEDLE POSITION" button. 2. Hook of needle threader does not fit into the eye of needle. 2. Set needle at proper position by "NEEDLE POSITION" button. 1. Upper threading is not correct. 1. Re-thread upper thread. 2. Set of bobbin thread is not correct. 2. Set bobbin properly and pull out the bobbin thread. 3. Combination of fabric, thread and needle is not correct. 3. Check "RELATIVE CHART OF SEWING FABRICS, NEEDLE AND THREAD". 4. Check if the thread tension is set at "AUTO" position. 4. See page "THREAD TENSION".