Brother International S-7200B Instruction Manual - English

Brother International S-7200B Manual

|

View all Brother International S-7200B manuals

Add to My Manuals

Save this manual to your list of manuals |

Brother International S-7200B manual content summary:

- Brother International S-7200B | Instruction Manual - English - Page 1

S-7200B INSTRUCTION MANUAL Please read this manual before using the machine. Please keep this manual within easy reach for quick reference. SINGLE NEEDLE DIRECT DRIVE STRAIGHT LOCK STITCHER WITH THREAD TRIMMER - Brother International S-7200B | Instruction Manual - English - Page 2

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety instructions and the explanations given in the instruction manual. With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts such as - Brother International S-7200B | Instruction Manual - English - Page 3

indications and their meanings This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure safe operation of this machine and to prevent accidents and example, the symbol at left means "you must make the ground connection".) S-7200B i - Brother International S-7200B | Instruction Manual - English - Page 4

problems with correct operation. Installation Machine installation should only be carried out by a qualified technician. Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done. The sewing machine the oil out of the reach of children. ii S-7200B - Brother International S-7200B | Instruction Manual - English - Page 5

reach of children. Use only the proper replacement parts as specified by Brother. Maintenance and inspection Maintenance and inspection of the sewing machine should only be carried out by a qualified technician. Ask your Brother dealer or a qualified electrician to carry out any maintenance and - Brother International S-7200B | Instruction Manual - English - Page 6

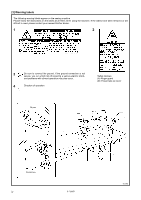

labels The following warning labels appear on the sewing machine. Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are difficult to read, please contact your nearest Brother dealer. 1 2 3 Be sure to connect the ground. If - Brother International S-7200B | Instruction Manual - English - Page 7

CONTENTS 1. NAMES OF MAJOR PARTS 1 2. MACHINE SPECIFICATIONS 2 3. INSTALLATION 3 3-1. Table Adjusting the thread take-up spring 50 13-4. Adjusting arm thread guide R 51 13-5. Adjusting the presser foot height 51 13-6. TROUBLESHOOTING 57 14-1. Sewing 57 14-2. Error code displays 62 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 8

lever (5) Presser foot (7) Control box panel (9) Power switch (11) Reverse lever (13) Machine pulley (15) Cotton stand Safety devices (16) Thread take-up cover (2) Thread wiper (-4[][] Stitch length dial (14) Operation panel (Models with operation panel) 3630M (17) Finger guard 1 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 9

, 450W) Microprocessor *...When sewing at speeds of 4,000 rpm or higher, set the stitch length to 4.2 mm or less. -305 -405 4,500 rpm* 1.2 mm #19 - #22 Rotary hook -33S -43S Lubricated / for light materials -303, -403 -333, -433 Lubricated / for medium materials -305 -405 Lubricated / for heavy - Brother International S-7200B | Instruction Manual - English - Page 10

your Brother dealer or a qualified electrician for any electrical work that may need to be done. The sewing machine weighs sewing machine. The sewing machine should be plugged directly into an AC wall outlet. Operation problems may result if extension cords are used. Carrying the machine The machine - Brother International S-7200B | Instruction Manual - English - Page 11

and should be strong enough to hold the weight and with-stand the vibration of the sewing machine. Drill holes as indicated in the illustration below. Cotton stand hole Cord hole Head pcs] (4) Spring washers [3 pcs] (5) Washers [3 pcs] 2. Connecting rod (6) Connecting rod (7) Nut 2091M S-7200B 4 - Brother International S-7200B | Instruction Manual - English - Page 12

(left) [2 pcs] (2) Head cushions (right) [2 pcs] (3) Oil pan 3632M 5. Rubber cushions (1) Rubber cushions [2 pcs] (2) Nails [4 pcs] 6. Knee lifter complying bar (3) Knee lifter complying bar 2094M 5 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 13

into the table hole. If the head rest (3) is not pushed in as far as it will go, the machine head will not be sufficiently stable when it is tilted back. 3633M 8. Operation panel (Models with operation panel) (1) securely clamped and so that the cotton stand (1) does not move. 3636M S-7200B 6 - Brother International S-7200B | Instruction Manual - English - Page 14

knee lifter plate (1) to a position where it is easy to use. 3637M 1. Turn the machine pulley so that the feed dog is below the top of the needle plate. 2. Lower the presser foot (5) by adjustment is completed, securely tighten the nut (9). Within 16 mm 3639M 7 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 15

machine should always be lubricated and the oil supply replenished before it is used for the first time, and also after long periods of non-use. Use only the lubricating oil (Nisseki Mitsubishi Sewing Lube 10N; VG10) specified by Brother. * If this type of lubricating oil is difficult to obtain - Brother International S-7200B | Instruction Manual - English - Page 16

can result in severe injury. CAUTION Contact your Brother dealer or a qualified electrician for any electrical work problems with correct operation may also occur. 3-4-1. Opening the control box cover (1) Screw (2) Cover 3-4-2. Connecting the cords 3642M 1. Sewing machine cords 3643M 9 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 17

. All cords that come out from the control box should be secured to the cord holder (3) using the repeat cable tie (1), otherwise vibration from the sewing machine may cause the cords to become disconnected, which can cause problems with the operation of the control box. Cords 3645M S-7200B 10 - Brother International S-7200B | Instruction Manual - English - Page 18

wire is the ground wire.) 2. Insert the plug into a properly-grounded AC power supply. NOTE: Do not use extension cords, otherwise machine operation problems may result. Green and yellow wire (ground wire) Ground symbol 2112M 4. Ground wire (1) Ground wire (2) Screw [With washer] (3) Screw Oil - Brother International S-7200B | Instruction Manual - English - Page 19

touch any of the moving parts or press any objects against the machine while sewing, as this may result in personal injury or damage to the machine. 2114M 1. Turning on the power out and the needle then rises above the needle plate and stops. 2117M S-7200B 12 - Brother International S-7200B | Instruction Manual - English - Page 20

4. PREPARATION BEFORE SEWING 4. PREPARATION BEFORE SEWING 4-1. Installing the needle CAUTION Turn off the power switch before installing the needle. The machine may operate if the treadle is depressed by mistake, which could result in injury. Front 1. Turn the machine pulley to move the needle bar - Brother International S-7200B | Instruction Manual - English - Page 21

machine. 3650M 1. Turn on the power switch. 2. Place the bobbin (1) onto the bobbin winder shaft (2). 3. Wind the thread several times around the bobbin (1) in the direction tension spring (2), and then pull it out from the thread guide (3). 4. Check that the bobbin turns clockwise when the thread - Brother International S-7200B | Instruction Manual - English - Page 22

machine pulley and raise the thread take-up (1) before threading the upper thread. This will make threading easier and it will prevent the thread from coming out at the sewing be. (The numbers on the dial are for use as a guide. The length of the finished stitches may vary depending on the S-7200B - Brother International S-7200B | Instruction Manual - English - Page 23

4. PREPARATION BEFORE SEWING 4-7. Using the thread wiper (-4[][] specifications) Press the thread wiper switch (1) to the side. If this is done, the thread wiper Using the knee lifter 3653M 2209M The presser foot (2) can be raised by pressing the knee lifter plate (1). 2131M 3654M S-7200B 16 - Brother International S-7200B | Instruction Manual - English - Page 24

keys cannot be operated while sewing is in progress. Select the keys and set the number of stitches before starting sewing. • In the case of B, C and D stitch number displays is sewn continuously. After the sewing machine sews a full cycle of stitches set by A, B, C and D, the thread is - Brother International S-7200B | Instruction Manual - English - Page 25

carried out after the set number of stitches have been sewn. 2152M (14) Half stitch key When the sewing machine is stopped, the needle bar can be moved up and down by pressing this key. 2153M (15) Lower its initial value and to cancel warning conditions. (Refer to p.24.) 2156M S-7200B 18 - Brother International S-7200B | Instruction Manual - English - Page 26

before sewing of the set number of start backtack stitches is complete, end backtacking will not be carried out. • If the indicator of the thread trimming lock key is illuminated, the sewing machine will stop in the needle up position without thread trimming being carried out. 2160M 19 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 27

the sewing machine sewing> When the AUTO key is pressed to turn on the automatic sewing function, operation will be carried out automatically from continuous backtack sewing through to thread trimming just by depressing the treadle once, without needing to keep it depressed continuously. S-7200B - Brother International S-7200B | Instruction Manual - English - Page 28

set. 2 After the set number of stitches in E (fixed stitches) have been sewn, the sewing machine stops in the needle position that has been set by the needle up/down key (refer to p.25). After this, normal sewing is carried out if the treadle is depressed. 2159M 3 After the thread is trimmed - Brother International S-7200B | Instruction Manual - English - Page 29

backtack sewing function. • If changing the number of start and end backtack stitches in A, B, C and D, press the name label stitch key to turn off the name label function before making the change. (The ABCD display will show the number of stitches and the settings can then be changed.) S-7200B 22 - Brother International S-7200B | Instruction Manual - English - Page 30

key and end backtack key can be pressed to turn on the backtack sewing function. • If changing the number of end backtack stitches indicated in C and D, press the pleat presser sewing key to turn off the pleat presser sewing function before making the change. (The CD display will show the number of - Brother International S-7200B | Instruction Manual - English - Page 31

treadle returns to the neutral position and the sewing machine stops, the sewing machine will not start up again even if the sewing will be possible when the treadle is depressed. If you press and hold the RESET key (2) for 2 seconds or more, the display will return to the initial value. S-7200B - Brother International S-7200B | Instruction Manual - English - Page 32

that the correction icon (21) illuminates, correction sewing can be carried out. If the sewing machine is stopped, sewing will be carried out at slow speed (220 down position when the treadle is returned to the neutral position and sewing stops. • When the needle up icon (23) is illuminated, the - Brother International S-7200B | Instruction Manual - English - Page 33

used to accept function settings. MAX key (5) This key is used to change the maximum sewing speed. * Refer to the Service Manual for details on using these keys. 2212M 6-4. Resetting all settings to their defaults While the above display appears, normal operation will then be possible. S-7200B 26 - Brother International S-7200B | Instruction Manual - English - Page 34

) NOTE The control box panel will not operate when the machine head operation panel is connected. 7-1. Names and functions Power • This lets you adjust the sewing speed when the treadle is fully depressed. • The sewing speed becomes faster when the speed control displays error codes. 27 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 35

7. USING THE CONTROL BOX PANEL (BASIC OPERATIONS) 7-2. Sewing start and end backtacking and continuous backtacking and locking thread trimming Thread trimming not locked (3) to set the mode in the bottom row of the stitch number display. 3661M (Continued on next page) S-7200B 28 - Brother International S-7200B | Instruction Manual - English - Page 36

: 7) 3138M 1. Press the start backtack key (2) so that "d" is displayed. 2. Press the end backtack key (3) to set the number of stitches for d. (Example: 6) 3139M 29 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 37

bottom row of the stitch number display. 8 Exiting setting mode Set the power switch (1) to OFF. 3664M Refer to the next page for details on sewing "Start and end backtacking" or "Continuous backtacking". 3665M - Brother International S-7200B | Instruction Manual - English - Page 38

and end backtack sewing method> 1 the neutral position, the sewing machine will continue operating until sewing machine stops in the needle up position. NOTE: If the treadle is depressed backward before sewing locked" is set, the sewing machine will stop in the out, the sewing machine will stop at - Brother International S-7200B | Instruction Manual - English - Page 39

: The control box panel will not operate when the machine head operation panel is connected. 8-1. Before setting any needle down stop position when the treadle is returned to the neutral position and sewing stops. 1 1. Press the start backtack key (4) so that "n" is displayed S-7200B 32 - Brother International S-7200B | Instruction Manual - English - Page 40

-3 to ON. (The settings will be locked.) 8-4. Correction sewing This sews at slow speed (220 rpm) while the actuator is being pressed when the sewing machine is stopped. 1 1. Press the start backtack key (4) so more) 3 Set DIP switch -3 to ON. (The settings will be locked.) 3150M 33 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 41

display. 2. Press the end backtack key (2) to set the value. Becomes lower 2 Becomes higher Set DIP switch -3 to ON. (The settings will be locked.) 3152M S-7200B 34 - Brother International S-7200B | Instruction Manual - English - Page 42

sewing machine. If the machine is used without these devices attached, injury may result. Turn off the power switch at the following times. The machine to start sewing. 9-2. Backtacking 3668M 3669M When the actuator (1) or the reverse lever (2) is pressed during sewing, the feed direction will be - Brother International S-7200B | Instruction Manual - English - Page 43

condensed stitches as follows. Sewing direction Condensed stitches 3671M 3672M Unlocked Locked 1. Lift up the dial lock lever (3) to release the lock. 2. Turn the stitch length dial (4) to the stitch length to be used for condensed stitches. 3. Tilt back the machine head. 4. Loosen the - Brother International S-7200B | Instruction Manual - English - Page 44

the thread tension CAUTION Turn off the power switch before removing or inserting the bobbin case. The machine may operate if the treadle is depressed by mistake, which could result in injury. Good even the presser foot. 2. Adjust by turning the tension nut (2). Becomes stronger 2178M 37 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 45

from the needle tips will be reduced; if the tension is reduced, the lengths will be increased. Adjust by turning the pretension (1). Shorter 3676M Longer S-7200B 38 - Brother International S-7200B | Instruction Manual - English - Page 46

machine sewing take-up support shaft support shaft (4) counterclockwise so that the groove (5) is facing straight downward. 5. With the thread take-up support shaft (4) pushed in as far as it will go, first tighten the set screw (2) until it touches the screw stop on the thread take-up support - Brother International S-7200B | Instruction Manual - English - Page 47

out each day in order to maintain the perfomance of this machine and to ensure a long service life. Furthermore, if the sewing machine has not been used for a long period of time, carry the bobbin into the bobbin case (4), and then place the bobbin case (4) back into the machine. 2184M S-7200B 40 - Brother International S-7200B | Instruction Manual - English - Page 48

back the machine head. When the machine head is angle of the machine head. Tilt back the machine head while the Look at the oil window (1) from directly in front. 2. If the oil Mitsubishi Sewing Lube 10N; VG10) specified by Brother. (3) securely. 4. Return the machine head to its original position. - Brother International S-7200B | Instruction Manual - English - Page 49

it is bent or if the tip is broken. 2. Check that the upper threads have been threaded correctly. (Refer to page 15.) 3. Carry out a test sewing. 3681M S-7200B 42 - Brother International S-7200B | Instruction Manual - English - Page 50

apply grease and carry out the reset procedure. * If you continue to use the sewing machine after carrying out the reset procedure but without applying grease, problems with the sewing machine may result. Use Brother-specified grease (SA7300-001). Using the tube 3682M 43 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 51

CLEANING Marked red Turn the machine pulley to lower the needle set screws in order to push the grease in. 5. Turn the machine pulley by hand to move the needle bar up and down several Depress the treadle to run the sewing machine for 1 second or more. 8. Turn the power switch to "OFF - Brother International S-7200B | Instruction Manual - English - Page 52

apply grease and carry out the reset procedure. * If you continue to use the sewing machine after carrying out the reset procedure but without applying grease, problems with the sewing machine may result. Use Brother-specified grease (SA7300-001). Using the tube 3682M 45 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 53

and the set screws in order to push the grease in. 5. Turn the machine pulley by hand to move the needle bar up and down several times in 7. Carry out the reset procedure given below. After the grease has been applied, carry out be locked.) S-7200B 46 - Brother International S-7200B | Instruction Manual - English - Page 54

amount" above. * Turn the adjusting screw (3) and check the lubrication amount repeatedly until the lubrication amount is correct. 4. Check the lubrication amount again after the sewing machine has been used for approximately two hours. 47 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 55

ADJUSTMENTS CAUTION Maintenance and inspection of the sewing machine should only be carried out by a qualified technician. Ask your Brother dealer or a qualified electrician to carry out actuator (1) to the preferred position or . 3. Tighten the two screws (2). 3687M 3688M S-7200B 48 - Brother International S-7200B | Instruction Manual - English - Page 56

too much space between the machine head and the table > The standard amount of clearance between the machine head and the table hole is 1.5 mm (1) so that the washer (2) is on the machine head side as shown in Figure [B]. * If operate. 3.5 mm or more Sewing machine Table Clearance is too large - Brother International S-7200B | Instruction Manual - English - Page 57

take-up spring (1) varies in accordance with the machine specifications as shown in the table. -[][]S specifications spring (1) is at the same height as the base of the thread guide (3), and then measure the tension of the thread take-up spring (1). 35N 0.3 - 0.5N 3694M S-7200B 50 - Brother International S-7200B | Instruction Manual - English - Page 58

the adjustable range for arm thread guide R (1). * To adjust the position, loosen the screw (2) and then move arm thread guide R (1). ・ When sewing thick material, move arm thread guide R (1) to the left. pressure using the adjustment screw (4), and then tighten the nut (3). 2278M 51 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 59

3696M 1. Turn the pulley until the feed dog (1) rises to the highest position. 2. Tilt back the machine head. 3. Loosen the screw (2). 4. Turn the feed lifting rock bracket stud (3) within a range of Becomes higher Standard Becomes higher Standard Becomes lower Becomes lower 2282M S-7200B 52 - Brother International S-7200B | Instruction Manual - English - Page 60

dog (1) to its highest position above the needle plate. 2. Tilt back the machine head. 3. Loosen the two set screws (4). 4. Turn the shaft (2) in the direction of the arrow within a range of 90° with respect to the standard is raised Raise the front Standard Lower the front 2285M 53 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 61

lowest position. 1. Turn the machine pulley to set the needle bar 1. Tilt back the machine head. 2. Loosen the the vertical cam (3) as a guide.) ・ To set to the in the direction of (B). direction of (C). Refer to [C] in the illustration.) NOTE: Do not turn the vertical cam (3) too far in the direction - Brother International S-7200B | Instruction Manual - English - Page 62

lower edge of the needle bar bush D (2) as shown in the illustration. 1. Turn the machine pulley to raise the needle bar (1) from its lowest position until reference line (b) is aligned with 0.6 - 1.1 mm for -[][]5 models. 0.4 - 0.7mm 0.6 - 1.1mm 2293M 3700M 55 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 63

depression sensitivity adjustment> If the machine starts running at low speed presser foot (1) in accordance with the material. 1. Turn the sewing machine pulley by hand to move the feed dog (2) below the * After making the adjustment, sew a piece of material to check the floating amount. Raise - Brother International S-7200B | Instruction Manual - English - Page 64

the power cord before carrying out troubleshooting. The machine may operate if the treadle is depressed by mistake, which could result in injury. 14-1. Sewing Items with a "*" in the "Page" column should only be checked by a qualified technician. Problem 1 Upper thread is not tight. Possible - Brother International S-7200B | Instruction Manual - English - Page 65

TROUBLESHOOTING Problem 5 Skipped stitches at sewing start Thread unravelling at sewing in the bobbin case. Is the sewing speed too fast at the sewing start? Use the slow start feature. 38 Is the sewing speed too fast? Use the sewing speed control keys to gradually reduce the sewing speed. 18 - Brother International S-7200B | Instruction Manual - English - Page 66

14. TROUBLESHOOTING Problem 9 Lower thread is tangled at the sewing start. Spinning of bobbin Brother. Is the needle bent or is the needle tip broken? Replace the needle if it is bent or broken. Is the needle properly installed? If it is incorrect, install the needle correctly. Is the machine - Brother International S-7200B | Instruction Manual - English - Page 67

TROUBLESHOOTING Problem 13 Broken needles 0469M 14 Oil gauge (1) is not visible in oil gauge window. Possible cause Is the material being pushed or pulled with excessive force during sewing oil. Page 13 54* 55* 54* 8 2195M 15 Machine does not operate Is the power supply connector when power is - Brother International S-7200B | Instruction Manual - English - Page 68

14. TROUBLESHOOTING Problem 18 Nothing appears on the operation panel display. Possible cause Is the power supply connector disconnected from the control box? Insert the connector securely. This display is to notify you that it is time to apply grease. Apply grease. 10* 3154M 43, 45* 61 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 69

14. TROUBLESHOOTING 14-2. label Is the power supply voltage abnormally high? Check. Problem with control box. Replace the control box. Is the electrical * 3155M 10* 3156M 11 Has the machine locked up? Turn off the power and then turn the machine pulley by hand and check that it turns easily - Brother International S-7200B | Instruction Manual - English - Page 70

TROUBLESHOOTING Error code Err 5 (Safety switch operated) Possible cause Is the machine connector inside the control box disconnected? Insert the connector securely. Page 10* Err 6 (Voltage drop) Is the machine head tilted back? Return the machine problem sewing machine as normal. Problem - Brother International S-7200B | Instruction Manual - English - Page 71

14. TROUBLESHOOTING Page * ** 3702M * ** 3158M * ** 3703M Err 15 Problem with motor. Replace the motor. ** (Problem with sewing machine motor operation) Problem with power stroke". * (Treadle pedal position error) Problem with treadle unit. Replace the treadle unit. ** S-7200B 64 - Brother International S-7200B | Instruction Manual - English - Page 72

TROUBLESHOOTING Error code Err 21 (Thermistor error) Possible cause Is connector CN16 inside the control box disconnected? Insert the connector securely. Page * 3159M Err 100 This appears on the display when the sewing machine not solve the problem, contact the place of purchase. 65 S-7200B - Brother International S-7200B | Instruction Manual - English - Page 73

14. TROUBLESHOOTING (Error code) If an error code is displayed 13 Treadle unit error 14 Head detector unit error 15 Problem with sewing machine motor operation 16 Thread trimming solenoid timeout 18 EEROM error 19 does not solve the problem, contact the place of purchase. S-7200B 66 - Brother International S-7200B | Instruction Manual - English - Page 74

INSTRUCTION MANUAL http://www.brother.com/ 15-1, Naeshiro-cho, Mizuho-ku, Nagoya 467-8561, Japan. Phone: 81-52-824-2177 © 2006 Brother Industries, Ltd. All Rights Reserved. S-7200B SA7308-001 E 2006.04. B (1)

S-7200B

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

SINGLE NEEDLE DIRECT DRIVE STRAIGHT LOCK STITCHER

WITH THREAD TRIMMER

INSTRUCTION MANUAL