Craftsman 3800 Operation Manual - Page 23

Problem, Correction

|

View all Craftsman 3800 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

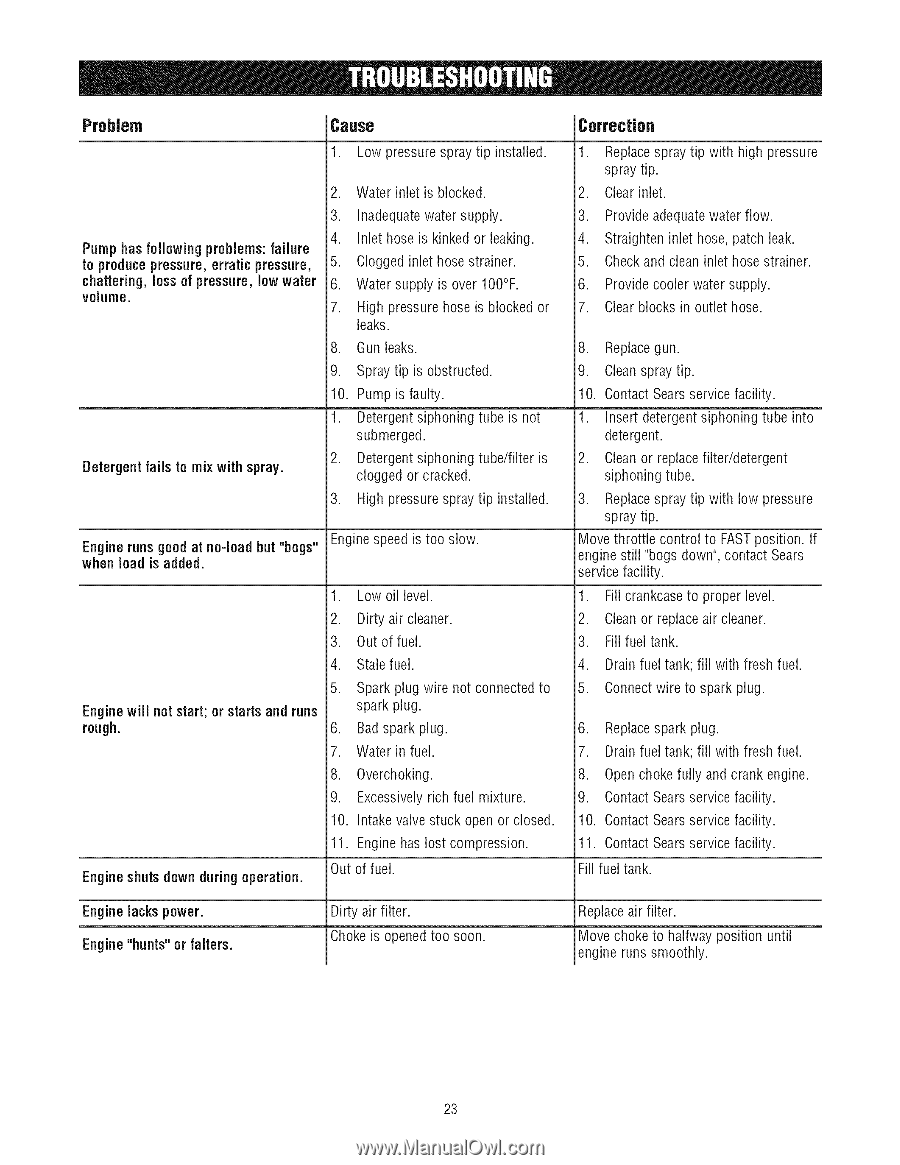

Problem Caus8 1. Low pressure spray tip installed. 2. Water inlet is blocked. 3. Inadequatewater supply. 4. Inlet hose is kinked or leaking. Pomp has following problems:failure to producepressure, erratic pressore, 5. Clogged inlet hose strainer. chattering, loss of pressure, low water 6. Water supply is over IO0°F. volome. 7. High pressure hose is blocked or leaks. 8. Gun leaks. 9. Spray tip is obstructed. 10. Pump is faulty. Detergent fails to mix with spray. 1. Detergentsiphoning tube is not submerged. 2. Detergentsiphoning tube/filter is clogged or cracked. 3. High pressure spray tip installed. Correction 1. Replacespray tip with high pressure spray tip. 2. Clear inlet. 3. Provide adequatewater flow. 4. Straighten inlet hose, patch leak. 5. Checkand clean inlet hose strainer. 6. Provide cooler water supply. 7. Clear blocks in outlet hose. 8. Replacegun. 9. Cleanspray tip. 10. Contact Searsservice facility. 1. Insert detergent siphoning tube into detergent. 2. Cleanor replace filter/detergent siphoning tube. 3. Replacespray tip with low pressure spray tip. Engine runs good at no-load hut "bogs" Engine speed is too slow. when load is added, 1. Low oil level. 2. Dirty air cleaner. 3. Out of fuel. 4. Stale fuel. 5. Engine will not start; or starts and runs rough. 6. 7. Spark plug wire not connected to spark plug. Bad spark plug. Water in fuel. 8. Overchoking. 9. Excessivelyrich fuel mixture. 10. Intake valve stuck open or closed. 11. Engine has lost compression. Out of fuel. Engineshuts downduring operation. Move throttle control to FASTposition, if engine still "bogs down", contact Sears service facility. 1. Fiil crankcase to proper level. 2. Cleanor replace air cleaner. 3. Fiil fuel tank. 4. Drain fuel tank; fiil with fresh fuel. 5. Connectwire to spark plug. 6. Replacespark plug. 7. Drain fuel tank; fill with fresh fuel. 8. Open choke fully and crank engine. 9. Contact Searsservice facility. 10. Contact Searsservice facility. 11. Contact Searsservice facility. till fuel tank. Enginelacks power. Engine "hunts" or falters. Dirty air filter. Choke is opened too soon. Replaceair filter. Move choke to halfway position until engine runs smoothly. 23