Craftsman 88690 Operation Manual - Page 16

Maintenance, Schedule

|

View all Craftsman 88690 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

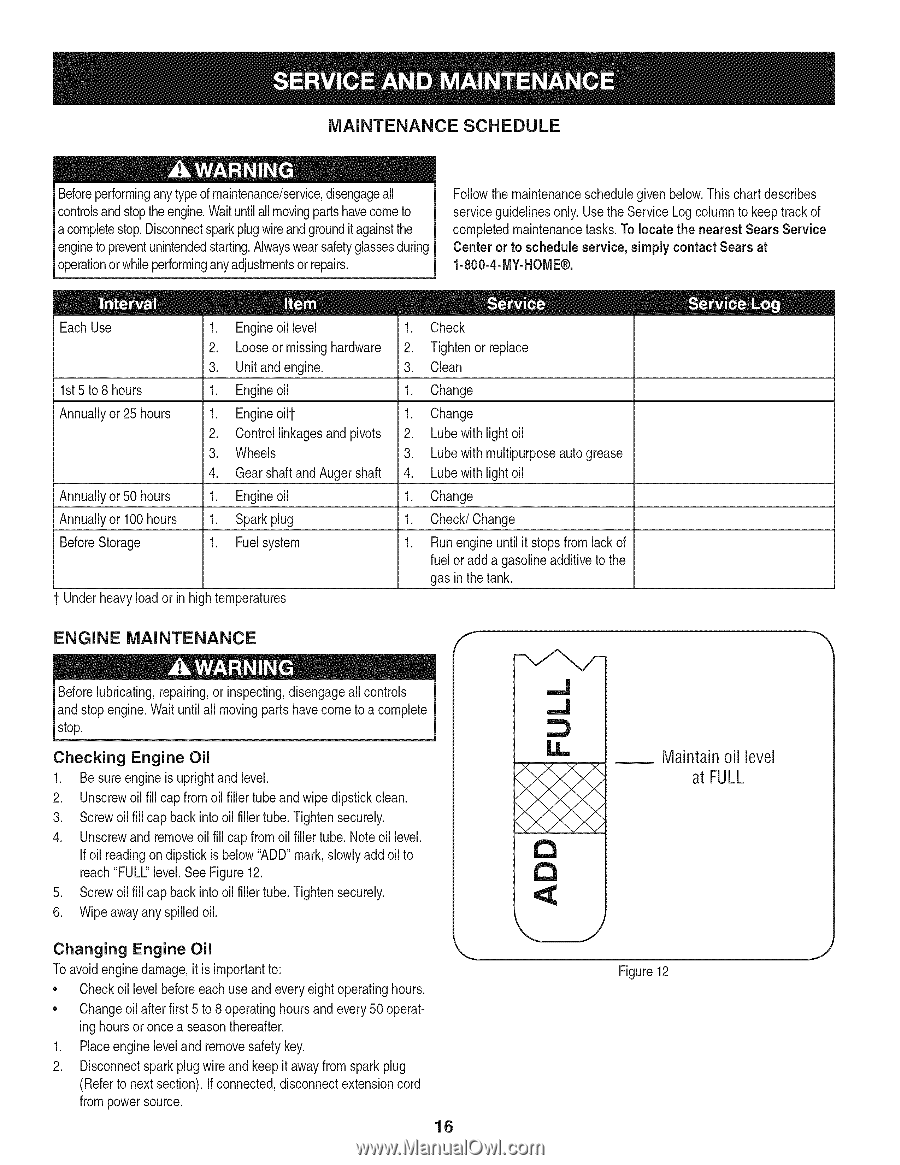

MAINTENANCE SCHEDULE Beforeperforminganytypeofmaintenance/servicdei,sengageall controlsand stoptheengineW. aituntilall movingpartshavecometo a completestop.Disconnecst parkplugwireandgrounditagainsthe enginetopreventunintendedstarting.Alwayswearsafetyglassesduring operationor whileperforminganyadjustmentsor repairs. Followthe maintenanceschedulegiven below.This chart describes serviceguidelinesonly. Usethe ServiceLog columnto keeptrackof completedmaintenancetasks.To locate the nearest Sears Service Centeror to scheduleservice,simplycontactSearsat 1-800-4-MY-HOME®. EachUse 1st5 to 8 hours Annuallyor 25 hours Annuallyor 50 hours Annuallyor 100 hours BeforeStorage 1. Engineoil level 2. Looseor missinghardware 3. Unitand engine. 1. Engineoil 1. Engineoi112. Controllinkagesand pivots 3. Wheels 4. Gearshaft and Augershaft 1. Engineoil 1. Sparkplug 1. Fuelsystem Underheavyload or inhigh temperatures = = 1. Check 2. Tightenor replace 3. Clean 1. Change 1. Change 2. Lubewith lightoil 3. Lubewith multipurposeautogrease 4. Lubewith lightoil 1. Change 1. Check/Change 1. Runengineuntilit stopsfrom lackof fuel or add a gasolineadditiveto the gas in thetank. ENGINE MAINTENANCE f Beforelubricating,repairing,or inspecting,disengageall controls Iand stop engine.Wait untilall movingpartshavecometo a complete [stop. Checking Engine Oil 1. Be sureengine is uprightand level. 2. Unscrewoil fill capfrom oil fillertubeand wipe dipstickclean. 3. Screwoil fill capback intooil fillertube. Tightensecurely. 4. Unscrewand removeoil fill cap from oil filler tube. Noteoil level. If oil readingon dipstick isbelow"ADD"mark,slowlyadd oil to reach"FULL"level.See Figure12. 5. Screwoil fill capback intooil fillertube. Tightensecurely. 6. Wipeawayany spilledoil. Changing Engine Oil Toavoidenginedamage,it is importantto: • Checkoil levelbeforeeachuseand every eightoperatinghours. • Changeoil afterfirst 5 to 8 operatinghoursand every 50 operat- ing hoursor oncea seasonthereafter. 1. Placeengineleveland removesafety key. 2. Disconnectspark plug wireand keepit awayfrom sparkplug (Referto next section). If connected,disconnectextensioncord from powersource. 16 ..J ,,.J U., a a Maintain oil level at FULL J Figure12