Craftsman 88690 Operation Manual - Page 23

and9ft-lbs.

|

View all Craftsman 88690 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

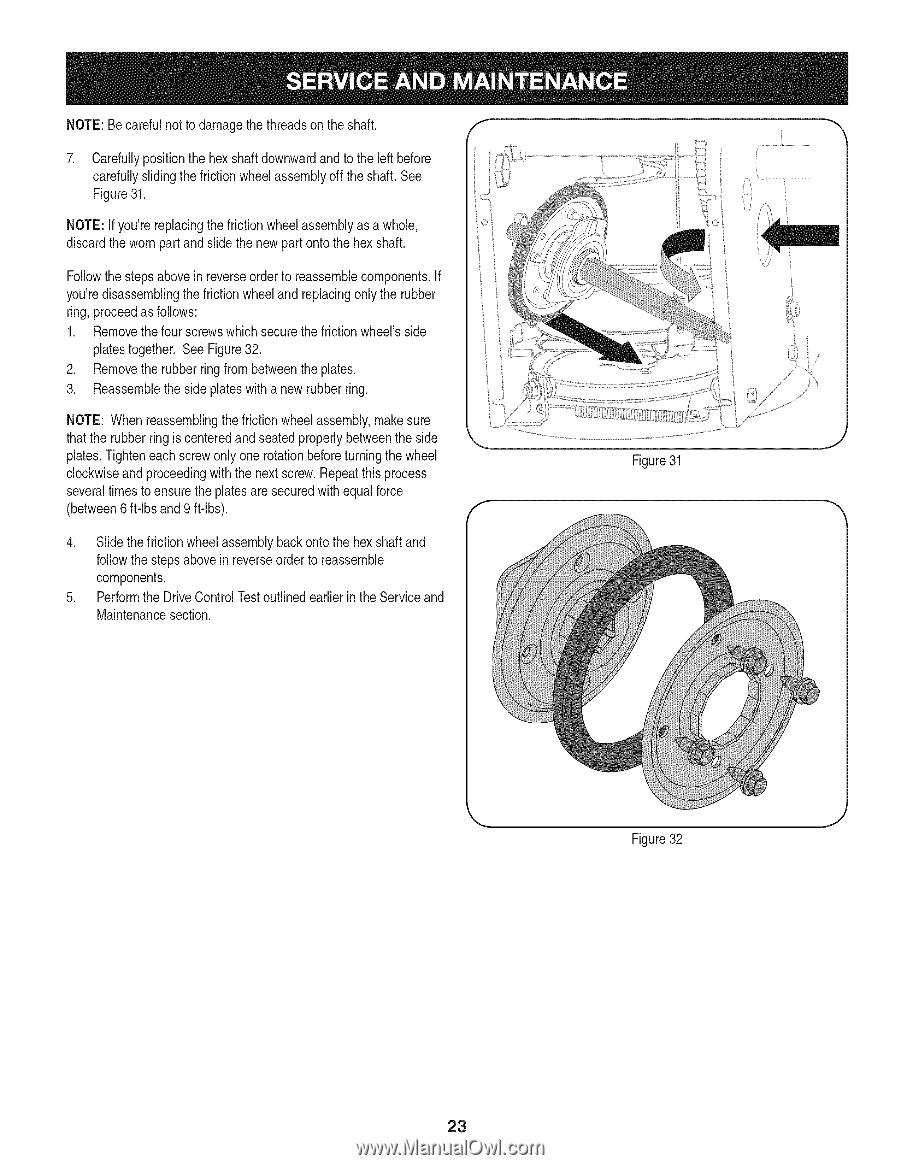

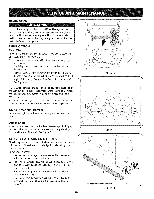

NOTEB:ecarefunlotodamagtheethreadosntheshaft, 7. Carefupllyositiothnehexshafdtownwaarnddtotheleftbefore carefusllylidintghefrictiownheealssembolfyftheshaftS. ee Figur3e1. NOTEIf:you'rreeplacitnhgefrictiownheealssembalsyawhole, discartdhewornparat ndslidethenewparot ntothehexshaft. FollotwhestepasbovienreversoerdetroreassemcbolemponenIfts. you'rdeisassembtlhinefgrictiownheealndreplacionnglytherubber ringp, roceeadsfollows: 1. Removtheefourscrewwshichsecurtehefrictiownheels'side platetsogetheSr.eeFigur3e2. 2. Removtheerubberirngfrombetweethneplates. 3. Reassemtbhleesideplatewsithanewrubberirng. NOTEW: herneassembtlhinegfrictiownheealssembmlya, kseure thatherubberirngiscentereadndseatepdroperblyetweethneside plateTs.ighteenachscrewonlyonerotatiobneforteurnintghewheel clockwiasendproceedwinigththenexst crewR.epeathtisprocess severtaiml estoensurteheplateasresecurewdithequafol rce (betwe6enft-lbasnd9ft-lbs). 4. Slidethefrictiownheealssembblaycokntothehexshafatnd followthestepasbovienreversoerdetroreassemble components. 5. PerfortmheDrivCe ontrTolesot utlineedarlieinrtheServicaend Maintenasneccetion. Figur3e1 ... j Figure32 23