Dewalt D24000 Instruction Manual - Page 13

Troubleshooting Guide - stand

|

View all Dewalt D24000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

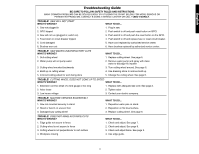

English Troubleshooting Guide BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A DEWALT SERVICE CENTER OR CALL 1-(800)-4-DEWALT. TROUBLE! SAW WILL NOT START WHAT'S WRONG? 1. Saw not plugged in 2. GFCI tripped 3. Saw will not run (plugged in; switch on) 4. Fuse blown or circuit breaker tripped 5. Cord damaged 6. Brushes worn out WHAT TO DO... 1. Plug in saw. 2. Push switch to off and push reset button on GFCI. 3. Push switch to off and push the reset button on the GFCI. 4. Push switch to off and replace fuse or reset circuit breaker. 5. Have cord replaced by authorized service center. 6. Have brushes replaced by authorized service center. TROUBLE! SAW MAKES UNSATISFACTORY CUTS WHAT'S WRONG? 1. Dull cutting wheel 2. Water pump will not pump water 3. Cutting wheel mounted backwards 4. Build up on cutting wheel 5. Incorrect cutting wheel for work being done WHAT TO DO... 1. Replace cutting wheel. See page 6. 2. Remove water pump and spray with clean water to dislodge the impeller 3. Turn cutting wheel around. See page 6. 4. Use dressing stone to remove build up. 5. Change the cutting wheel. See page 6. TROUBLE! CUTTING WHEEL DOES NOT COME UP TO SPEED WHAT'S WRONG? WHAT TO DO... 1. Extension cord too small of a wire gauge or too long 1. Replace with adequate size cord. See page 2. 2. Arbor loose 2. Tighten arbor 3. Low house voltage 3. Contact your electric company. TROUBLE! MACHINE VIBRATES EXCESSIVELY WHAT'S WRONG? 1. Saw not mounted securely to stand 2. Stand or bench on uneven floor 3. Damaged saw cutting wheel WHAT TO DO... 1. Reposition water pan on stand. 2. Reposition on flat level surface. 3. Replace cutting wheel. See page 6. TROUBLE! DOES NOT MAKE ACCURATE CUTS WHAT'S WRONG? 1. Edge guide not secure to fence 2. Cutting wheel is not square to fence 3. Cutting wheel is not perpendicular to cart surface 4. Workpiece moving WHAT TO DO... 1. Check and adjust. See page 7. 2. Check and adjust. See page 9. 3. Check and adjust fence. See page 9. 4. Use edge guide. 11