Dewalt D55140 Instruction Manual - Page 15

Troubleshooting Guide, Troubleshooting Codes - pressure switch for

|

View all Dewalt D55140 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

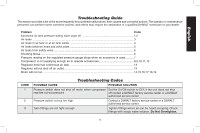

English Troubleshooting Guide This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or maintenance personnel can perform some corrective actions, and others may require the assistance of a qualified DEWALT technician or your dealer. Problem Code Excessive air tank pressure-safety valve pops off 1,2 Air leaks ...3 Air leaks in air tank or at air tank welds 4 Air leaks between head and valve plate 5 Air leaks from safety valve...6 Knocking Noise...6 Pressure reading on the regulated pressure gauge drops when an accessory is used 7 Compressor is not supplying enough air to operate accessories 8,9,10,11,12 Regulator knob has continuous air leak 13 Regulator will not shut off air outlet 13 Motor will not run ...14,15,16,17,18,19 CODE 1 2 3 Troubleshooting Codes POSSIBLE CAUSE POSSIBLE SOLUTION Pressure switch does not shut off motor when compressor Set the On/Off switch to OFF, if the unit does not shut reaches cut-out pressure off contact a DEWALT factory service center or a DEWALT authorized service center. Pressure switch cut-out too high Contact a DEWALT factory service center or a DEWALT authorized service center. Tube fittings are not tight enough Tighten fittings where air can be heard escaping. Check fittings with soapy water solution. Do Not Overtighten. 15