Dewalt DWF83PT Instruction Manual - Page 15

Troubleshooting Guide

|

View all Dewalt DWF83PT manuals

Add to My Manuals

Save this manual to your list of manuals |

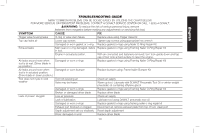

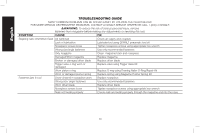

Page 15 highlights

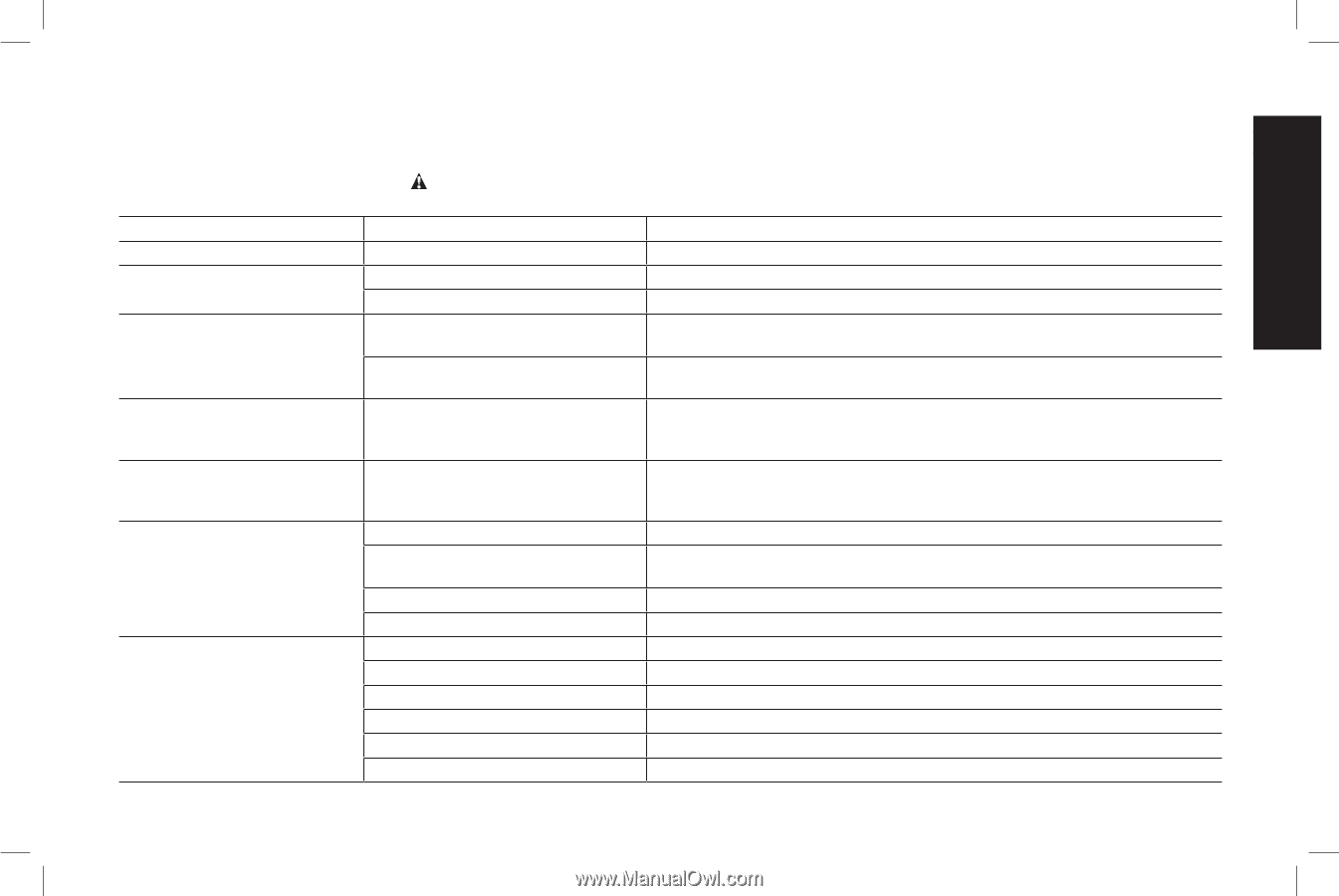

English TROUBLESHOOTING GUIDE MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A DeWALT SERVICE CENTER OR CALL 1-(800)-4-DeWALT. WARNING: To reduce the risk of serious personal injury, remove fasteners from magazine before making any adjustments or servicing this tool. SYMPTOM CAUSE FIX Trigger valve housing leaks O-ring or valve stem failure Replace valve using Trigger Valve Kit Top cap leaks air Loose cap screws Tighten cap screws using appropriate hex wrench Damaged or worn gasket or o-ring Replace gasket/o-rings using Nailer O-Ring Repair Kit Exhaust leaks Main seal or o-ring damaged, debris Replace gasket/o-rings using Framing Nailer O-Ring Repair Kit in tool. Engine in actuated position. With air connected and fasteners removed, turn tool upside down and tap cap of tool onto a hard surface to reset the engine. Air leaks around nose when tool is at rest. (Driver blade in up position.) Damaged or worn o-rings Replace gasket/o-rings using Framing Nailer O-Ring Repair Kit Air leaks around nose when Damaged or worn bumper tool is in actuated position. (Driver blade in down position.) Replace bumper using: Frame Nailer Bumper Kit Tool does not cycle in cold weather Tool not receiving air Valve may be frozen Check air supply Warm up tool. Lubricate with DeWALT Pneumatic Tool Oil or winter weight pneumatic oil containing ethylene glycol Damaged or worn o-rings Replace gasket/o-rings using Framing Nailer O-Ring Repair Kit Broken or damaged driver blade Replace driver blade Lack of power; sluggish Low air pressure Check air supply Lack of lubrication Lubricate tool using DeWALT pneumatic tool oil Damaged or worn o-rings Replace gasket/o-rings using framing nailer o-ring repair kit Exhaust port blocked or clogged Disconnect air, remove exhaust plate from top of tool, clean port Depth adjustment set too shallowly Reset depth adjustment Driver damaged or worn Replace driver blade 13