E-Z-GO Express L4 - Gas Owner Manual - Page 67

STARTER/GENERATOR BELT TENSION, Adjusting The Belt

|

View all E-Z-GO Express L4 - Gas manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 67 highlights

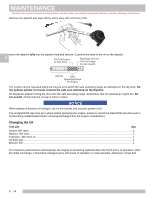

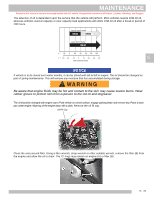

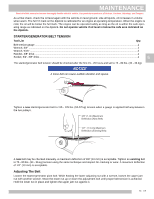

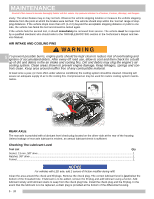

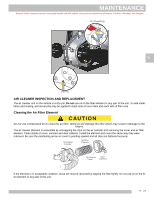

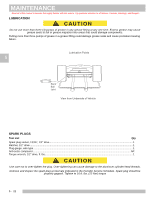

MAINTENANCE Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers. As a final check, check the oil level again with the vehicle on level ground. Like all liquids, oil increases in volume when warm. The full 'H' mark on the dipstick is calibrated for an engine at operating temperature. When the engine is cold, the oil will be below the full mark. The engine can be operated safely as long as the oil is within the safe operating range as indicated on the dipstick. Do not operate vehicle if oil level is below the safe area indicated on the dipstick. STARTER/GENERATOR BELT TENSION Tool List Qty. Belt tension gauge ...1 Wrench, 3/4" ...1 Wrench, 9/16" ...2 Ratchet, 3/8" drive...1 Socket, 3/4", 3/8" drive...1 5 The starter/generator belt tension should be checked after the first 15 - 20 hours and set to 75 - 80 lbs. (34 - 36 kg) NOTICE A loose belt can cause audible vibration and squeal. Tighten a new starter/generator belt to 115 - 125 lbs. (52-57 kg) tension when a gauge is applied half way between the two pulleys. 3/8" (1 cm) Maximum Deflection (New Belt) 1/2" (1.3 cm) Maximum Deflection (Existing Belt) A new belt may be checked manually. A maximum deflection of 3/8" (10 mm) is acceptable. Tighten an existing belt to 75 - 80 lbs. (34 - 36 kg) tension using the same technique and inspect for cracking or wear. A maximum deflection of 1/2" (13 mm) is acceptable. Adjusting The Belt Loosen the starter/generator pivot bolt. While holding the lower adjusting nut with a wrench, loosen the upper jam nut with another wrench. Move the lower nut up or down the adjustment bolt until proper belt tension is achieved. Hold the lower nut in place and tighten the upper jam nut against it. 5 - 17