E-Z-GO Express L6 - Electric Owner Manual - Page 70

Battery Replacement

|

View all E-Z-GO Express L6 - Electric manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 70 highlights

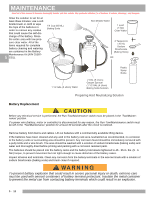

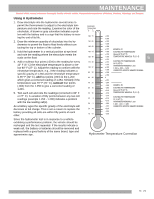

MAINTENANCE Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers. Allow the solution to set for at least three minutes; use a soft bristle brush or cloth to wipe the tops of the batteries in order to remove any residue that could cause the self-discharge of the battery. Rinse the entire area with low pressure clear water. All of the items required for complete battery cleaning and watering are contained in the Battery Maintenance Kit (P/N 25587- 5 G01). 1/4 Cup (60 ML) Baking Soda Non-Metalic Wand 1 quart (1 liter) Clear Water 2 Teaspoons (10 ml) Sodium Bicarbonate (Baking Soda) OR Battery Replacement Plastic Spray Bottle 1 1/2 GAL (6 Liters) Water 2 GAL (8 Liters) Gargen Sprayer (1 1/2 GAL (6 Liters) Baking Soda Solution Preparing Acid Neutralizing Solution Before any electrical service is performed, the Run-Tow/Maintenance switch must be placed in the 'Tow/Maintenance' position. If a power wire (battery, motor or controller) is disconnected for any reason, the Run-Tow/Maintenance switch must be left in the 'Tow/Maintenance' position for at least 30 seconds after the circuit is restored. Remove battery hold downs and cables. Lift out batteries with a commercially available lifting device. If the batteries have been cleaned and any acid in the battery rack area neutralized as recommended, no corrosion to the battery racks or surrounding area should be present. Any corrosion found should be immediately removed with a putty knife and a wire brush. The area should be washed with a solution of sodium bicarbonate (baking soda) and water and thoroughly dried before priming and painting with a corrosion resistant paint. The batteries should be placed into the battery racks and the battery hold downs tightened to 45 - 55 in. lbs. (5 - 6 Nm) torque, to prevent movement but not tight enough to cause distortion of the battery cases. Inspect all wires and terminals. Clean any corrosion from the battery terminals or the wire terminals with a solution of sodium bicarbonate (baking soda) and brush clean if required. To prevent battery explosion that could result in severe personal injury or death, extreme care must be used with aerosol containers of battery terminal protectant. Insulate the metal container to prevent the metal can from contacting battery terminals which could result in an explosion. 5 - 18