E-Z-GO TXT - Electric Owner Manual - Page 29

Routine Maintenance, Tire Inspection, Rear Axle, Hardware

|

View all E-Z-GO TXT - Electric manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

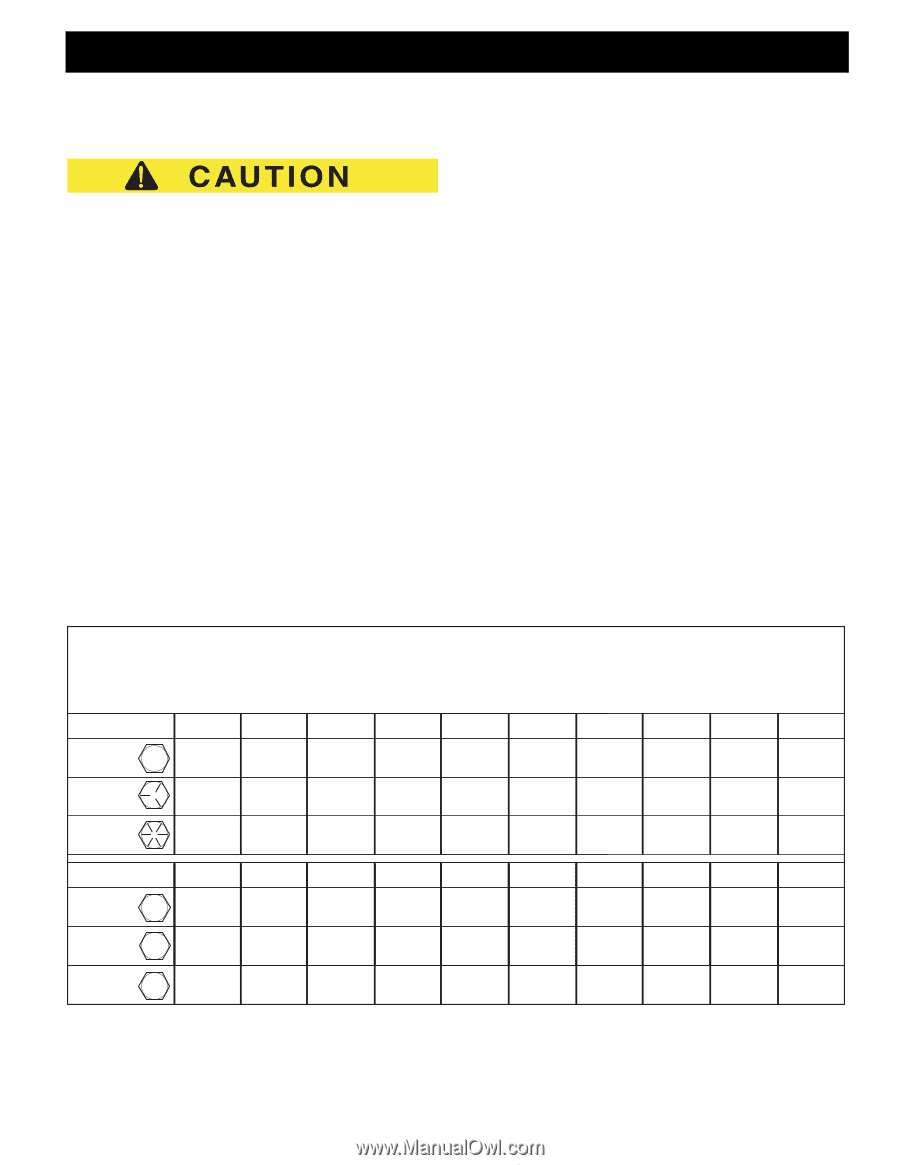

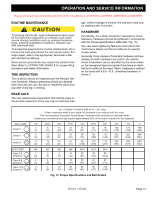

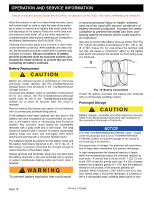

B OPERATION AND SERVICE INFORMATION Read all of manual to become familiar with this vehicle. Pay attention to all NOTICES, CAUTIONS, WARNINGS and DANGERS. ROUTINE MAINTENANCE B age. Unless leakage is evident, the lubricant need only be replaced after five years. To prolong vehicle life, some maintenance items must be serviced more frequently on vehicles used under severe driving conditions such as extreme tempkeratures, extreme dust/debris conditions, frequent use with maximum load. To access the powertrain for routine maintenance, lift or remove the seat and remove the rear access panel. For major repair, refer to the appropriate Technician's Repair and Service Manual. Some service procedures may require the vehicle to be lifted. Refer to LIFTING THE VEHICLE for proper lifting procedure and safety information. TIRE INSPECTION Tire condition should be inspected per the Periodic Service Schedule. Inflation pressures should be checked when the tires are cool. Be sure to install the valve dust cap after checking or inflating. HARDWARE Periodically, the vehicle should be inspected for loose fasteners. Fasteners should be tightened in accordance with the Torque Specifications table (Ref. Fig. 13). Use care when tightening fasteners and refer to the Technician's Repair and Service Manual for specific torque values. Generally, three classes of standard hardware and two classes of metric hardware are used in the vehicle. Grade 5 hardware can be identified by the three marks on the hexagonal head and grade 8 hardware is identified by 6 marks on the head. Metric hardware is marked on the head with 8.8 or 10.9. Unmarked hardware is Grade 2. REAR AXLE The only maintenance required for the first five years is the periodic inspection of the rear axle for lubricant leak- BOLT SIZE Grade 2 Grade 5 Grade 8 BOLT SIZE Class 5.8 (Grade 2) 5.8 Class 8.8 (Grade 5) 8.8 Class 10.9 (Grade 8) 10.9 ALL TORQUE FIGURES ARE IN FT. LBS. (Nm) Unless otherwise noted in text, tighten all hardware in accordance with this chart. This chart specifies 'lubricated' torque figures. Fasteners that are plated or lubricated when installed are considered 'wet' and require approximately 80% of the torque required for 'dry' fasteners. 1/4" 5/16" 3/8" 7/16" 1/2" 9/16" 5/8" 3/4" 7/8" 1" 4 8 15 24 35 55 75 130 125 190 (5) (11) (20) (33) (47) (75) (102) (176) (169) (258) 6 13 23 35 55 80 110 200 320 480 (8) (18) (31) (47) (75) (108) (149) (271) (434) (651) 6 18 35 55 80 110 170 280 460 680 (8) (24) (47) (75) (108) (149) (230) (380) (624) (922) M4 M5 M6 M8 M10 M12 M14 1 2 4 10 20 35 55 (2) (3) (6) (14) (27) (47) (76.4) 2 4 7 18 35 61 97 (3) (6) (10) (24) (47) (83) (131) 3 6 10 25 49 86 136 (4) (8) (14) (34) (66) (117) (184) Fig. 13 Torque Specifications and Bolt Grades Owner's Guide Page 13