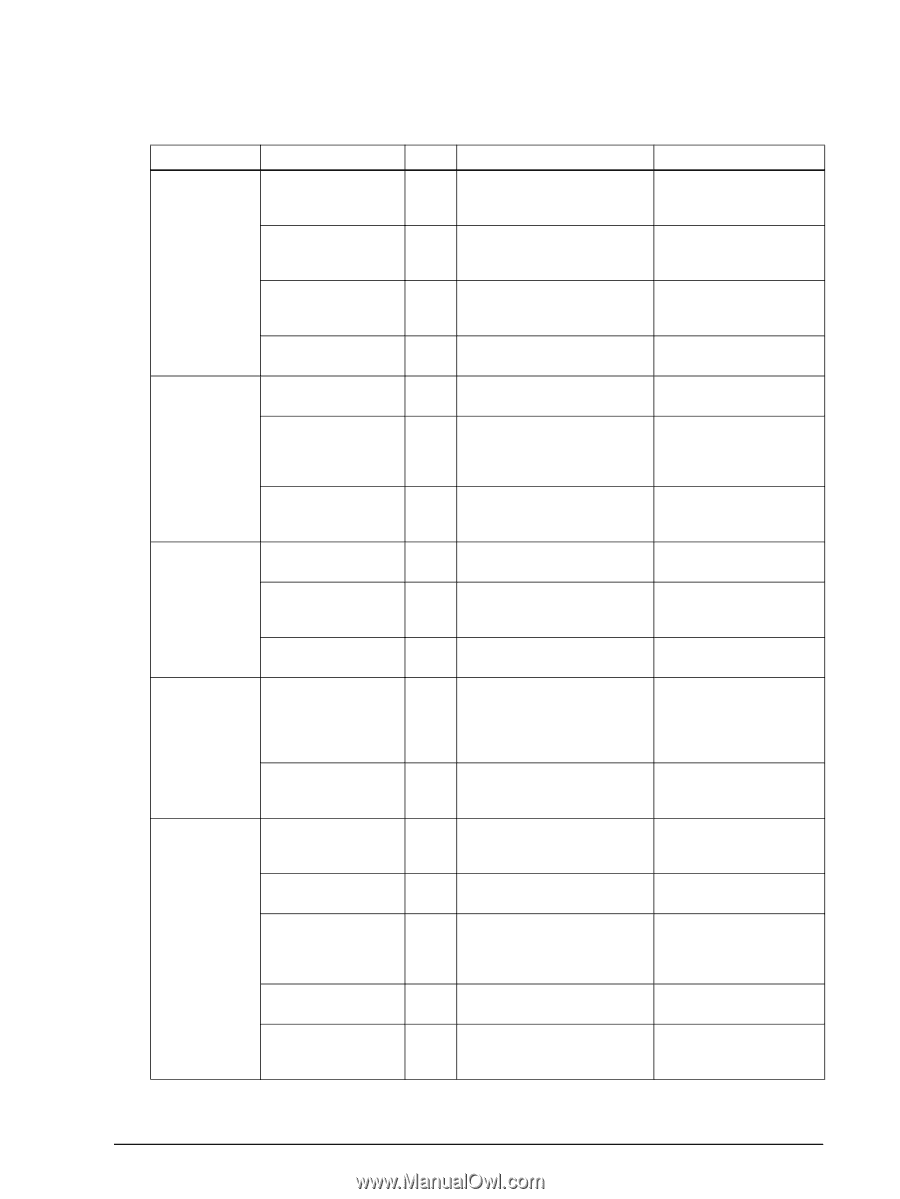

Epson TM U200D Technical Reference - Page 89

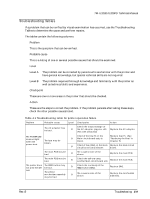

Table 4-2 Troubleshooting table for bad printing, Problem, Probable cause, Level, Checkpoint, Action

|

View all Epson TM U200D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 89 highlights

TM-U200D/U200PD Technical Manual Table 4-2 Troubleshooting table for bad printing Problem Probable cause Level Checkpoint Action The printer does not print. (The Motor, carriage operates, but nothing is printed, or the print color is light.) The ribbon in the ribbon cassette may be bad. The platen gap may be incorrect. The common line of the Print head unit may be bad. The FPC, head may be bad. A Check if the color of the ribbon is faded or the ribbon is wrinkled or torn. Replace the ribbon cassette. B Check the platen gap. (standard: 0.55 mm ±0.05 mm) Adjust the platen gap. (See "Adjustments" in Chapter 5.) B Check the continuity of the common line. Replace the Print head unit. B Check the continuity of the common line. Replace the FPC, head. The FPC, head may be bad. B Check the continuity of the F PC, head. Replace the FPC, head. Dots are missing continuously. (A specific dot is not printed.) The drive coil of the Print head unit may be bad. The dot wires of the Print head unit may be bad. Using the tester, check the B resistance of the corresponding Replace the Print head drive coil. (Standard: 19.2 ohm unit. ±5%) B Check if the dot wires are broken. Replace the Print head unit. The FPC, head may be bad. B Check the continuity of the FPC, head. Replace the FPC, head. Dots are missing The Print head unit occasionally. may be bad. Check if there are paper Remove any paper B particles or ink on the tips of the particles or ink, or replace dot wires of the Print head unit. the Print head unit. The Print head unit may be worn. B The cause is none of the above. Replace the Print head unit. Paper particles or Check if any paper particles or foreign substances foreign substances are Remove any paper may be attached to B attached to the Pulley, belt particles or foreign The character gears or pulley, belt drive, Pulley, belt tension, and substances. width is incorrect. driving or the belt. belt. Gears or Pulley, belt drive or the belt may be damaged or worn. B Check the wear and damage of the Pulley, belt drive, Pulley, belt tension, and belt. Replace any worn or damaged parts. The operation of the paper supply may be incorrect. A Check if the specified paper roll is used. Use the correct paper roll. (See "Paper Specifications" in Chapter 1.) The paper path may be incorrect. A Check if the paper supply path Remove paper particles is blocked. and foreign substances. Paper is not fed. (Printing is performed on one line.) The connector is not inserted correctly. Make sure that the pin of the PF A motor cable is inserted in the connector CN6 of the main Reinsert the connector. circuit board. The Roller, paper feed may be bad. B Check the wear and damage Replace the Roller, paper of the surface of the roller. feed. The Roller, paper hold ass'y may be worn or damaged. B Check the wear and damage of the rollers of the Roller, paper hold ass'y. Replace the Roller, paper hold ass'y. Rev. B Troubleshooting 4-11