Garmin GT41-TH - Stainless Steel Thru-Hull DownVü/SideVü 500 W CHIRP 2 - Page 4

Non-cored/Fiberglass Boat Hull Installation, Instructions

Page 4 highlights

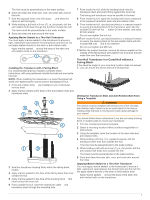

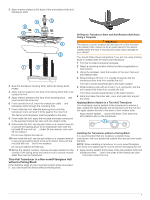

Installing the Transducer without a Fairing Block It is recommended that two installers complete these instructions, with one positioned outside the boat and one inside the boat. NOTE: When installing a transducer in a non-cored fiberglass hull, avoid over-tightening the nuts to prevent damaging the hull. 1 Apply marine sealant to the base of the anti-rotation bolts and transducer stem , and to the sides of the transducer plate Á that must contact the hull.  Drilling the Transducer Stem Hole and the Anti-Rotation Bolt Holes in a Non-Cored or Fiberglass Hull Before you can drill holes for the anti-rotation bolts, you must drill the hole for the transducer stem, and you must cut the fairing block (Cutting the Fairing Block). WARNING The device must be installed with at least one of the included anti-rotation bolts. Failure to do so could result in the device rotating while the boat is moving and could cause damage to your vessel. 2 From outside the hull, insert the transducer through the mounting hole and seat it firmly against the hull. 3 From inside the hull, apply the included anti-seize compound to the exposed transducer stem and anti-rotation bolts. 4 From inside the hull, use slip-joint pliers or a crescent wrench to secure the included 35 mm hull nut , 26 mm nylon à washer , and 24 mm rubber washer to the transducer Ä Å stem. Do not over-tighten the hull nut. 5 From inside the hull, use slip-joint pliers or a crescent wrench to secure the included M8 nuts and 8 mm nylon washers to Æ the anti-rotation bolts. Do not over-tighten the M8 nuts. 6 Before the sealant hardens, remove all excess sealant on the outside of the exterior hull to ensure smooth water flow over the transducer. You should follow these instructions when you are using a fairing block to mount the transducer on a boat that does not have a cored fiberglass hull. 1 Select a mounting location without surface irregularities or obstructions. 2 Using the template, mark the location of the stem hole and anti-rotation bolts. 3 Drill a 3 mm (1/8 in.) pilot hole and hull at the stem hole location, from outside the hull. The hole must be perpendicular to the water surface. 4 If the vessel has a fiberglass hull, place masking tape over the pilot hole and surrounding area outside the hull to prevent damage to the fiberglass. 5 If you taped over the pilot hole, use a utility knife to cut out the hole in the tape. 6 While holding a 25 mm (1 in.) spade bit plumb, cut a hole from outside the hull at the stem hole location. The hole must be perpendicular to the water surface. 7 Sand and clean the area around the hole. 8 While holding a drill with a 9 mm (3/8 in.) bit plumb, drill the anti-rotation bolt holes through the hull. The holes must be perpendicular to the water surface. 9 Sand and clean the area around the holes. Applying Marine Sealant to a Thru-Hull Transducer You must apply marine sealant to the transducer to ensure a tight, waterproof seal between the fairing block and the hull. Do not apply sealant directly to the stem or anti-rotation bolts. Apply marine sealant around the base of the stem and À anti-rotation bolts on the transducer. Non-cored/Fiberglass Boat Hull Installation Instructions Thru-Hull Transducer in a Non-cored/Fiberglass Hull with a Fairing Block If the deadrise angle of your mounting location exceeds 5°, you should use a fairing block to mount the device. Installing the Transducer with a Fairing Block It is recommended that two installers complete these instructions, with one positioned outside the boat and one inside the boat. NOTE: When installing the transducer in a cored fiberglass hull, avoid over-tightening the nuts to prevent damaging the hull. 1 If the anti-rotation bolts are installed on your transducer, À remove them. 4