HP 9000 rp4410-4 Site Preparation Guide, Third Edition - HP 9000 rp4410/rp4440 - Page 33

Metallic Particulate Contamination

|

View all HP 9000 rp4410-4 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 33 highlights

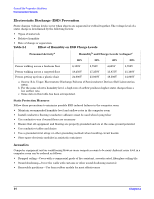

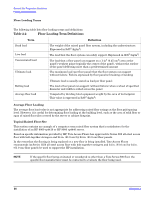

General Site Preparation Guidelines Environmental Elements Specifically, disk drives, tape drives, and some other mechanical devices can have bearing failures resulting from airborne abrasive particles. Dust may also blanket electronic components like printed circuit boards, causing premature failure due to excess heat and humidity build up on the boards. Other failures to power supplies and other electronic components can be caused by metallically conductive particles, including zinc whiskers. These metallic particles are conductive and can short circuit electronic components. Use every effort to ensure that the environment is as dust- and particulate-free as possible. See the following heading titled Metallic Particulate Contamination for additional details. Smaller particles can pass through some filters, and over a period of time, cause problems in mechanical parts. Small dust particles can be prevented from entering the computer room by maintaining the air conditioning system at a high static air pressure level. Other sources of dust, metallic, conductive, abrasive, or microscopic particles can be present. Some sources of these particulates are: • Subfloor shedding • Raised floor shedding • Ceiling tile shedding These particulates are not always visible to the naked eye. A good check to determine their possible presence is to check the underside of the tiles. The tile should be shiny, galvanized, and free from rust. The computer room should be kept clean. The following guidelines are recommended: • Smoking-Establish a no-smoking policy. Cigarette smoke particles are eight times larger than the clearance between disk drive read/write heads and the disk surface • Printer-Locate printers and paper products in a separate room to eliminate paper particulate problems • Eating or drinking-Establish a no-eating or drinking policy. Spilled liquids can cause short circuits in equipment such as keyboards • Tile floors-Use a dust-absorbent cloth mop rather than a dry mop to clean tile floors Special precautions are necessary if the computer room is near a source of air pollution. Some air pollutants, especially hydrogen sulfide (H2S), are not only unpleasant but corrosive as well. Hydrogen sulfide damages wiring and delicate sound equipment. The use of activated charcoal filters reduces this form of air pollution. Metallic Particulate Contamination Metallic particulates can be especially harmful around electronic equipment. This type of contamination may enter the data center environment from a variety of sources, including but not limited to raised floor tiles, worn air conditioning parts, heating ducts, rotor brushes in vacuum cleaners, or printer component wear. Because metallic particulates conduct electricity, they have an increased potential for creating short circuits in electronic equipment. This problem is exaggerated by the increasingly dense circuitry of electronic equipment. Over time, very fine whiskers of pure metal can form on electroplated zinc, cadmium, or tin surfaces. If these whiskers are disturbed, they may break off and become airborne, possibly causing failures or operational interruptions. For over 50 years, the electronics industry has been aware of the relatively rare but possible threat posed by metallic particulate contamination. During recent years, a growing concern has developed in computer rooms where these conductive contaminants are formed on the bottom of some raised floor tiles. Although this problem is relatively rare, it may be an issue within your computer room. Since metallic contamination can cause permanent or intermittent failures on your electronic equipment, HP strongly recommends that your site be evaluated for metallic particulate contamination before installation of electronic equipment. Chapter 2 33