HP Indigo 30000 Color Pyramid - Press Baseline and Maintenance -- CA493-02110D - Page 4

Procedures, Press baseline, Verifying site conditions, Verifying print quality

|

View all HP Indigo 30000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

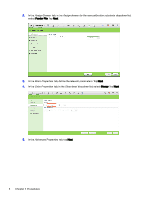

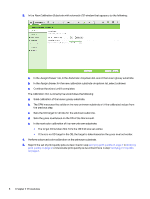

2 Procedures It describes the procedure on how to perform color related baseline and full color calibrations for known and unknown substrate types. Press baseline It explains the baseline of press. Verifying site conditions It explains the site conditions to be verified. ● Required ambient temperature: 20 - 25 °C (68 - 77 °F) ● Required ambient relative humidity: 50 - 70% non-condensing. Verifying print quality Follow these steps for verifying print quality. 1. Make sure the ILP is in good condition, that is, the applicator and anilox roller are clean and provide good priming to the substrate. 2. Supplies: Go to Menu > Press Status > Counters > Supplies. Verify that the blanket and PIP foil are neither old nor brand new. The recommended age is 2k-30k impressions. Impression paper should be in good condition as well. 3. Ink properties: Check conductivity with an external meter, and density using the press UI. 4. Load to the feeder pile a reference substrate that is a known high gloss substrate. Define it accurately and define it as a calibration substrate. 5. Calibrate the spectrophotometer (SPM) at Menu > Print Quality > SPM Calibration. 6. Run a first transfer calibration. 7. Check ILP substrate priming using the primer indicator. If the results are not good, perform the ILP T1 and T2 calibration wizard. 8. Print four copies of each of the following jobs to evaluate the press mechanical status: ● Gray 20 ● CATP 9. Evaluate press print quality. If necessary, clean the BID developers, clean the cleaning station wiper, and perform any other activity to achieve best print quality. Best print quality includes no severe banding, no Color Plane Registration (CPR) problems, no transfer or memory problems. 2 Chapter 2 Procedures