HP Nr3600 White Paper: HP Drives Industry Standards for Rugged Computing - Page 3

Test descriptions, Unit meets Water Resistance specification - cd

|

UPC - 829160344027

View all HP Nr3600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

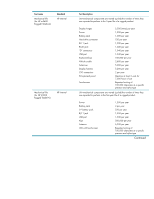

Test descriptions Both the HP Rugged Notebook and HP Rugged Tablet PC are intended for the most demanding environments and as such undergo the following tests. Because of its different usage model, the HP nr3600 Rugged Notebook undergoes four additional tests: 2 Vehicle Vibration tests, the Vehicle Shock test, and the Vehicle Crash test. The post-test pass and survival criteria are as follows: • No program data is lost • Unit meets Water Resistance specification • Unit functions (user can run applications) Table 1. HP Rugged Notebook and HP Rugged Tablet PC environmental test criteria Test name Standalone unit Shock (Drop) Vibration I (nonoperating) Vibration II (nonoperating) Vibration III (operating) Humidity Water resistance Standard Test description MIL-STD 810F, Method 516.5, Procedure IV, Modified MIL-STD 810F, Method 514.5, Procedure I, Category 24 MIL-STD 810F, Method 514.5, Procedure I, Category 24 ASTM 4169-99 Truck Assurance Level II, Schedule E MIL-STD 810F, Method 506.4, Procedure II, Time modified MIL-STD 810F, Method 506.4, Procedure II, Time modified Unit is dropped from a height of 3 feet to 2 inches of plywood over concrete onto each face, edge, and corner (26 contact points). Unit is nonoperating; display is closed; media bay contains CD-ROM disk; up to 2 units may be used; room temperature is about 20°C (68°F). Unit is powered on after each drop to check functionality. Unit passes if there is no loss of program data, the unit meets the Water Resistance specifications, and the user can run applications. Unit is placed on a vibration table with display facing up and then is subjected to a series of 3 tests for each of 3 orientations (axes) for 60 minutes each: front to back, side to side, and up and down. Unit is nonoperating; room temperature is about 20°C (68°F). Unit is powered on after testing. Random profile is studied. Unit is placed on a vibration table with display facing up and then is subjected to a series of three tests for each of three orientations (axes). The random vibration test lasts for 60 minutes and the sinusoidal vibration test lasts for 30 minutes each per axis: front to back, side to side, and up and down. Unit is nonoperating; room temperature is about 20°C (68°F). Unit is powered on after testing. Sine profile is studied. Unit is subjected to vibration for a duration of 90 minutes. Unit is operating. Unit is placed in a humidity chamber for ten 24-hour cycles at 30°C at 85% relative humidity (RH) noncondensing and 60°C at 95% RH noncondensing. Unit is operating, accessing hard disk drive. Unit is placed in a rain chamber that supplies simulated rain at a rate of no less than 4 inches per hour. Unit is tested for 10 minutes on each of 6 specific contact points with the display open. Unit is nonoperating. Continued