HP Nr3600 White Paper: HP Drives Industry Standards for Rugged Computing - Page 4

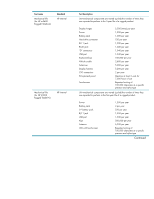

Continued, Test name, Standard, Test description

|

UPC - 829160344027

View all HP Nr3600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

Test name Dust and water High operating temperature Low operating temperature Low start temperature High storage temperature Low storage temperature Temperature shock Low pressure Standard IEC 60529 IP-54 MIL-STD 810F, Method 501.4, Procedure II MIL-STD 810F, Method 502.4, Procedure II, Modified Twinhead PA STD Appendix 13 MIL-STD 810F, Method 510.4, Procedure I MIL-STD 810F, Method 502.4, Procedure 1 MIL-STD 810F, Method 503.4, Procedure 1 MIL-STD 810F, Method 500.4, Procedure I, Procedure II modified Test description Unit is subjected to dust and then to water splashing. An IP number is assigned, specifying the environmental protection afforded by enclosures around electronic equipment. These ratings refer to specific tests. The IP number is made up of 2 digits, each signifying a separate component. For example, in the rating IP44 the first digit refers to the protection against solid objects such as dust, and the second digit refers to the protection against liquids. The higher the number, the better the protection. 1st digit: 5-Protected against dust, limited ingress (no harmful deposit) 2nd digit: 4-Protected against splashing water from all directions Unit is placed in a thermal chamber to operate at +60°C for five 24-hour cycles. Unit is operating, running a script file from a DOS window to keep resources running at 100% load. Unit is placed in a thermal chamber at less than --23°C for one 24-hour cycle. Unit is operating, running a script file from a DOS window to keep resources running at 100% load. Unit is placed in a thermal chamber for 1 hour at 0°C, then powered up and the display checked for visibility and unit functionality, and then powered down, for a series of 5 power-up tests. Unit is placed in a thermal chamber at 75°C for seven 24-hour cycles. Unit is nonoperating. Unit is placed in a thermal chamber at -55°C for one 24-hour cycle. Unit is nonoperating. Unit is alternately placed in 2 thermal chambers, one at -55°C and the other at +75°C, for 4-hour periods with no more than 5 minutes taken to change to the other chamber. Unit is nonoperating. Procedure I: First, unit is placed in a vacuum chamber at room temperature and held at PSIG of 10,000 feet for 1 hour. Unit is nonoperating. Procedure II: Unit is then placed in a vacuum chamber at room temperature and brought to PSIG of 30,000 feet at a rate of up to 2,000 feet per minute. Unit is operating, accessing disk. Continued