HP Scitex FB6100 Scitex Guide - Page 47

Approved Media Supplies

|

View all HP Scitex FB6100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

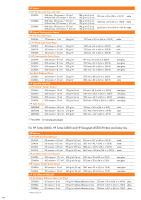

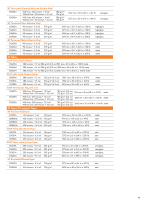

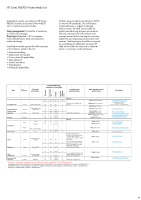

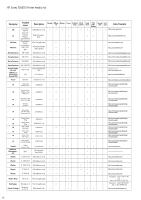

Approved Media Supplies HP Scitex FB7500 Printer Media list (for HP Scitex FB221 ink) Overview Listed below media was tested on Scitex FB7500 machine and printed with FB221 ink in the following print modes: POP 17| POP 34| POP 34 Text| POP 42| Production 63| Production 95. uv system: GUI defined setup accordingly to print mode. Loading/unloading mode: ¾ automatic. General limitations: Max media thickness: 25 mm. Max media weight for automatic loader: 20 Kg. FB221 ink shows good results in the ink chipping after cutting, adhesion to compressed carton, and flexibility abilities on corrugated carton. Listed below media has passed the following tests with limitations noted in the list: All tests were provided accordingly to ASTM or internal HP standards. The information contained herein is subject to change without notice. HP shall not be liable for media manufacturing process inconsistency. The only warranties for HP products and services are set forth in the express warranty statements accompanying such product and services. Nothing herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein. • Machine handling • Image quality • Cross cut • Tape adhesion • Dry abrasion • Finishing processes HP Scitex FB7500 Printer Media list (for HP Scitex FB221 ink) Lab Tests Media type Manufacturer Product Name Limitations Links/Contacts Abrasion Adhesion (tape) Cross Cut I-cut Guillotine cut Die cut CNC cut Folding Drill & Saw Varnish Heat bending Gluing to rigid back Compressed cardboard Smurfit Kappa Displayline √* √ N/A Xanita Xanita Mondi indoor, double side printable √ √ √ Mondi extreme, 1 side flexible fiber X √ N/A N/A N/A √ N/A N/A Gregoire Gre - screen √ √ N/A Corrugated cardboard Fluted Polypropylene Foamed PVC Carmel CCS Polygal Palram Alcan EB-flute √ √ Corrugated Polypropylene √ X Palight Sintra √ √ X � √ √ √ √ √ N/A √ N/A √ N/A N/A Limited adhesion for high ink √ � √ N/A N/A √ N/A N/A coverage in Production 63 print mode or faster √ N/A √ N/A N/A Foam board Alcan FomeCor N/A N/A N/A √ N/A N/A Polystyrene SAV Plazit 2001 Plazit 2001 Primex Plastics Corp. Avery Plaztyrene (GPPS) Plaztyrene (HIPS) HIPS MPI 3021 420 matt white Limited adhesion for high ink √ √ X X N/A о √ N/A � √ √ N/A coverage. Ink might crack on the edges after I-cutting √ √ √ о Limited handling in ¾ � о √ N/A N/A N/A N/A √ automatic loading mode. √√ √ Ink might crack after folding Synthetic paper Yupo FPU/FEU 250 N/A N/A о N/A о N/A N/A PVC film Klockner 0.28mm √ √ X √ о N/A N/A √ √ Re-board Design Force Re-board √ X X о N/A N/A N/A N/A о *√ - passed; � - passed with limitations; X - failed; о - not tested; N/A - not applicable о N/A N/A Limited adhesion for high ink coverage о N/A N/A Low adhesion for high ink coverage www.smurfitkappa.com www.xanita.com www.xanita.com www.gregoire-fr.com www.carmelccs.com www.polygal.com www.palram.com www.alcankapa.com www.alcankapa.com www.plazit.com www.primexplastics.com www.europe.averygraphics.com www.yupo.com www.designforce.se www.kpfilms.com 47