Hitachi NT65A3 Instruction Manual - Page 25

Operator troubleshooting

|

UPC - 717709007895

View all Hitachi NT65A3 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

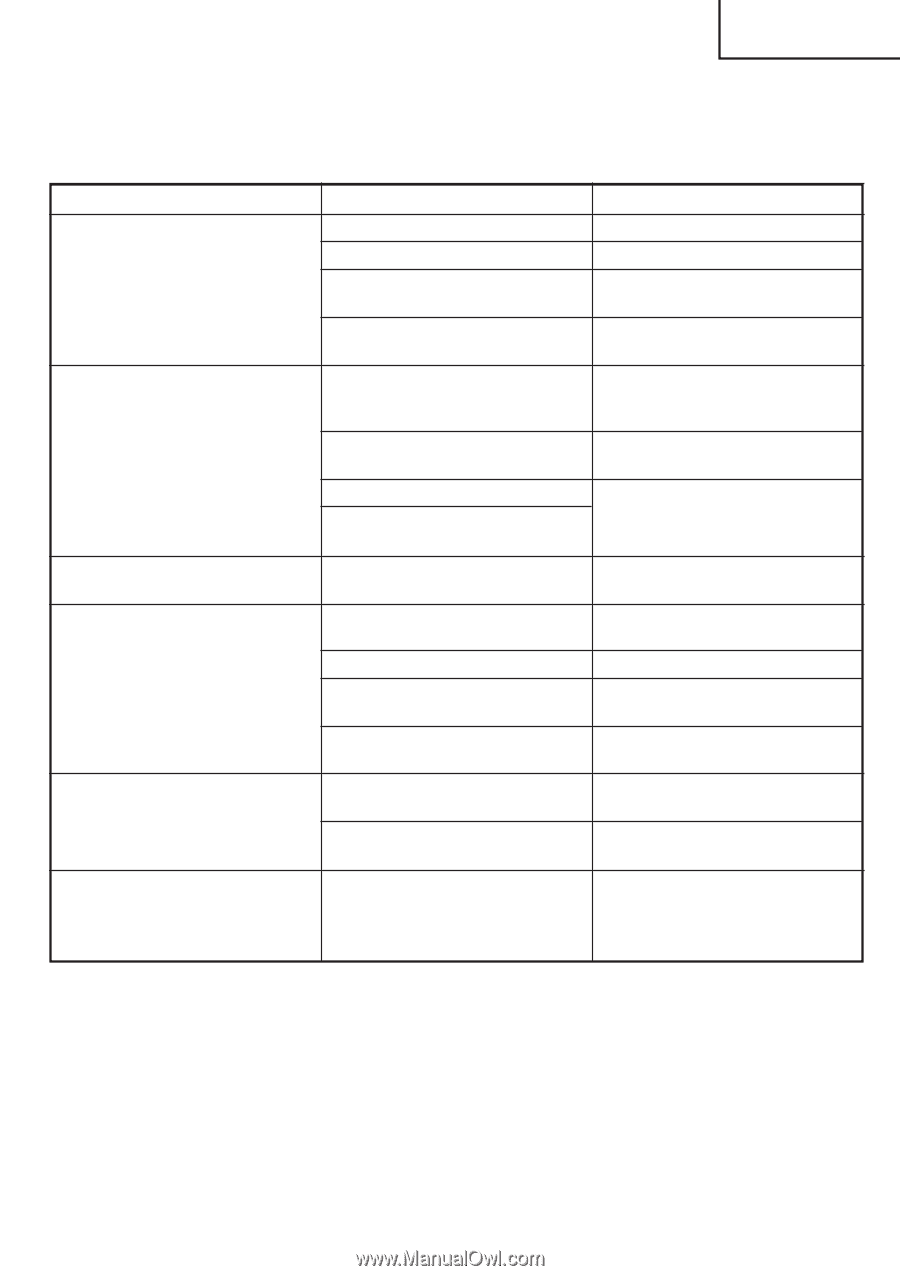

English Operator troubleshooting Most minor problems can be resolved quickly and easily using the table below. If problems persist, contact a Hitachi authorized service center for assistance. PROBLEM Nailer operates, but no nail is driven. Weak drive. Slow to cycle. CHECK METHOD Check for a jam. Nail feeder damaged? Ribbon spring weakend or damaged? Check for proper nails. Check air pressure. Drives too deep. Skipping nails. Intermittent feed. Nails jam. Driven nail is bent. --- Driver blade worn? Piston O-ring worm or damaged? Check air pressure. Check for proper nails. Nail feeder damaged? Ribbon spring weakend or damaged? Piston O-ring worn or damaged? Check for proper nails. Driver blade worn? Drives properly during normal operation, but does not drive fully at faster nailing speeds. Check inside diameter of air hose. CORRECTION Clear a jam page 22. Replace nail feeder. Replace ribbon spring. Use only recommended nails. Increase air pressure. (Do not exceed 120 psi (8.3 bar 8.5 kgf/cm2)) Use Hitachi pneumatic tool lubricant. Contact Hitachi for replacement. Reduce air pressure. (Adjust 70 - 120 psi) Use only recommended nails. Replace nail feeder. Replace ribbon spring. Contact Hitachi for replacement. Use only recommended nails. Contact Hitachi for replacement. Use larger air hose. 25