Husqvarna 435 Operation Manual - Page 28

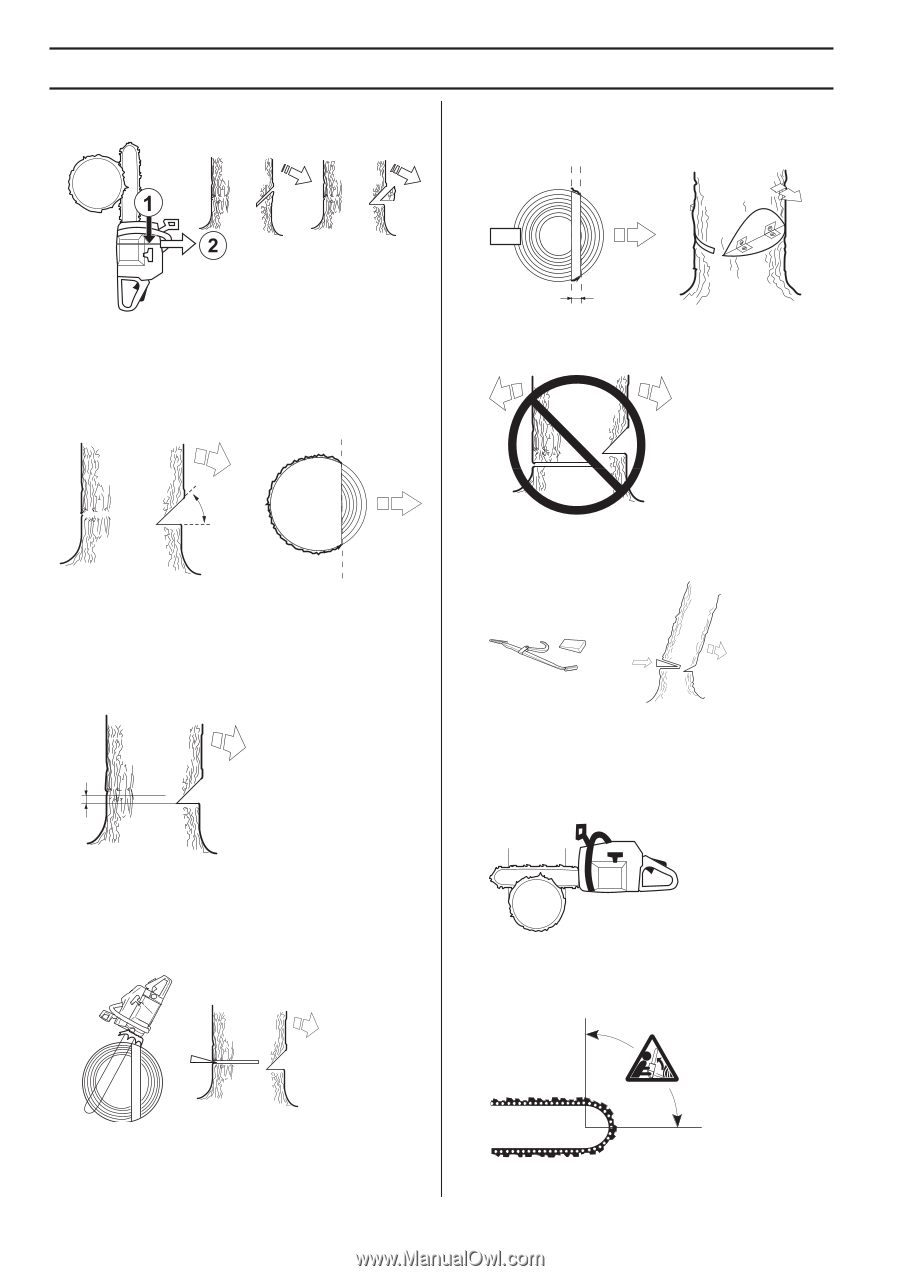

Felling cut, cuts and felling cut are badly placed.

|

View all Husqvarna 435 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 28 highlights

WORKING TECHNIQUES Next make the bottom cut so that it finishes exactly at the end of the top cut. trunk diameter. The uncut section of the trunk is called the felling hinge. The felling hinge controls the direction that the tree falls in. The directional cuts should run 1/4 of the diameter through the trunk and the angle between the top cut and bottom cut should be 45°. The line where the two cuts meet is called the directional cut line. This line should be perfectly horizontal and at right angles (90°) to the chosen felling direction. All control over the felling direction is lost if the felling hinge is too narrow or non-existent, or if the directional cuts and felling cut are badly placed. Felling cut The felling cut is made from the opposite side of the tree and it must be perfectly horizontal. Stand on the left side of the tree and cut on the pull stroke. Make the felling cut about 3-5 cm (1.5-2 inches) above the bottom directional cut. When the felling cut and directional cut are complete the tree should start to fall by itself or with the aid of a felling wedge or breaking bar. We recommend that you use a bar that is longer than the diameter of the tree, so that you can make the felling cut and directional cuts with single cutting strokes. See instructions under the heading Technical data section to find out which lengths of bar are recommended for your saw. Set the spike bumper (if one is fitted) just behind the felling hinge. Use full throttle and advance the chain/bar slowly into the tree. Make sure the tree does not start to move in the opposite direction to your intended felling direction. Drive a wedge or breaking bar into the cut as soon as it is deep enough. There are methods for felling trees with a diameter larger than the bar length. However these methods involve a much greater risk that the kickback zone of the bar will come into contact with the tree. Finish the felling cut parallel with the directional cut line so that the distance between them is at least 1/10 of the 28 - English 115 10 82-26 Rev.2 2008-06-03