JVC VN-V685U White paper: Thermal Simulation is Key to JVC CCTV Product Relia - Page 3

every 10° rise in internal temperature halves the life span, Why thermal simulation has become

|

View all JVC VN-V685U manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

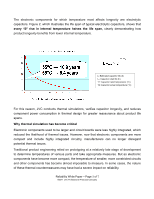

The electronic components for which temperature most affects longevity are electrolytic capacitors. Figure 2, which illustrates the life span of typical electrolytic capacitors, shows that every 10° rise in internal temperature halves the life span, clearly demonstrating how product longevity benefits from lower internal temperature. L: Estimated capacitor life (h) L0: Capacitor rated life (h) T1: Capacitor rated temperature (°C) T2: Capacitor actual temperature (°C) For this reason, JVC conducts thermal simulations, verifies capacitor longevity, and reduces component power consumption in thermal design for greater reassurance about product life spans. Why thermal simulation has become critical Electronic components used to be larger and circuit boards were less highly integrated, which reduced the likelihood of thermal issues. However, now that electronic components are more compact and include highly integrated circuitry, manufacturers can no longer disregard potential thermal issues. Traditional product engineering relied on prototyping at a relatively late stage of development to determine temperatures of various parts and take appropriate measures. But as electronic components have become more compact, the temperature of smaller, more constricted circuits and other components has become almost impossible to measure. In some cases, the nature of these thermal countermeasures may have had a severe impact on reliability. Reliability White Paper - Page 3 of 7 ©2011 JVC Professional Products Company