JVC VN-V685U White paper: Thermal Simulation is Key to JVC CCTV Product Relia - Page 5

Environmental initiatives

|

View all JVC VN-V685U manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

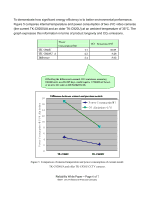

The following measures can be taken for sensitive internal components: modify the product body shape to facilitate component heat dissipation (radiation). modify the board pattern. investigate channels of direct heat dissipation from components to the product body. rearrange the board and component layout to separate heat-generating parts. determine any areas where energy is wasted and reduce load circuit consumption. make power circuits highly energy efficient. The process of conducting thorough and comprehensive thermal simulations prior to prototyping enables JVC engineers to eliminate thermal issues earlier in the product development cycle, which results in extremely stable and reliable finished products. Environmental initiatives Linked to JVC's goal of product reliability is another goal of creating products that have minimal environmental impact. Apart from the normal "best practice" manufacturing techniques, as well as recycling and waste management policies, JVC also strives to design products that operate with the absolute minimum power consumption. This drive toward greater energy efficiency also has a reciprocal impact on the ultimate reliability of the product. As mentioned, thermal simulation is very useful in controlling temperature in electronics, and one specific approach to keeping products cool is to reduce power consumption. Controlling temperature helps capacitors and circuits last longer. In thermal simulation, engineers seek better product reliability by controlling the heat generated inside (through dissipation and uniform internal distribution of heat), but the goal of energy efficiency involves minimizing this heat in the first place. Reliability White Paper - Page 5 of 7 ©2011 JVC Professional Products Company