LG HBLG2350E Service Manual - Page 3

Preface - air conditioner

|

View all LG HBLG2350E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

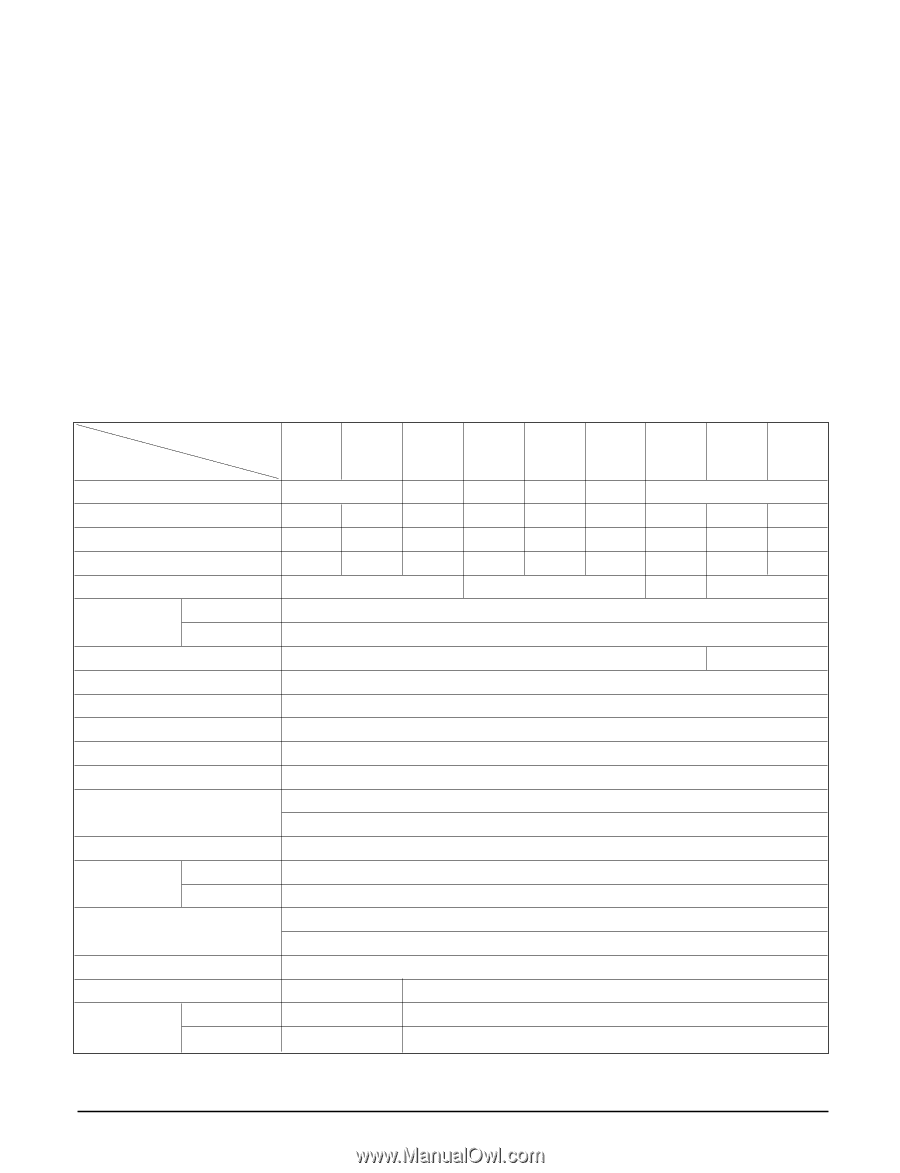

1. PREFACE This service manual provides various service information, including the mechanical and electrical parts, etc. This room air conditioner was manufactured and assembled under a strict quality control system. The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit. 1.1 SAFETY PRECAUTIONS 1.2 INSULATION RESISTANCE TEST 1. When servicing, set the POWER of CONTROL BOARD to Off and unplug the power cord. 2. Observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit. 3. After servicing, make an insulation resistance test to prevent the customer's exposure to shock hazards. 1. Unplug the power cord and connect a jumper between 2 pins (black and white). 2. The grounding conductor (green or green and yellow) is to be open. 3. Measure the resistance value with an ohm meter between the jumpered lead and each exposed metallic part on the equipment at all Mode [except POWER OFF]. 4. The value should be over 1 MΩ. 1.3 SPECIFICATIONS ITEMS MODELS M1804R WG1800R HBLG1800R LWM1836TASL WN1836QCG LWM1863QAS Y5USC18-6R LWN2131QAG WG2400R HBLG2400R M2403R LWN2432QAS Y5USC24-6R LWC243NSMM0 LWN2433TCS LWC243NSMM2 HBLG2350E POWER SUPPLY 1Ø, 208/230V, 60Hz 1Ø, 220V, 60Hz 1Ø, 220V, 60Hz 1Ø,208/230V,60Hz 1Ø, 220V, 60Hz 1Ø, 208/230V, 60Hz COOLING CAPACITY (Btu/h) 17,500/18,000 17,500 18,000 21,000 23,500/24,000 24,000 24,000 23,000 23,000/23.500 INPUT (W) 1,800/1,850 1,840 1,050 2,470 2,760/2,820 2,820 2,420 2,540 2,450/2,500 RUNNING CURRENT (A) 9.0/8.3 8.5 8.3 10.3 13.7/12.7 12.7/12.9 11.2 11.5 12.2/11.3 REFRIGERANT CHARGE (g) 710(25.1 OZ) 995(35.1 OZ)/980(34.6 OZ) 880(31 OZ) 985(34.7 OZ) OPERATING INDOOR (°C) 26.7(DB) 19.4(WB) TEMPERATURE OUTDOOR (°C) 35(DB) 23.9(WB) FAN, INDOOR BLOWER TURBO FAN, OUTDOOR PROPELLER TYPE FAN WITH SLINGER-RING FAN SPEEDS, FAN/COOLING 3/3 FAN MOTOR 6 POLES OPERATION CONTROL TOUCH PANEL ROOM TEMP. CONTROL THERMISTOR AIR DIRECTION CONTROL VERTICAL LOUVER(RIGHT & LEFT) HORIZONTAL LOUVER(UP & DOWN) CONSTRUCTION PROTECTOR POWER CORD COMPRESSOR FAN MOTOR DRAIN SYSTEM NET WEIGHT (lbs/kg) OUTSIDE DIMENSION (inch) (W x H x D) (mm) 120/54 26 x 1627/32 x 269/16 660 x 428 x 675 SLIDE IN-OUT CHASSIS INTERNAL OVERLOAD PROTECTOR INTERNAL THERMAL PROTECTOR 1.6m (3 WIRE WITH GROUNDING) ATTACHMENT PLUG(CORD-CONNECTED TYPE) DRAIN PIPE OR SPLASHED BY FAN SLINGER 143/65 26 x 1627/32 x 305/16 660 x 428 x 770 * DB:Dry Bulb ** WB:Wet Bulb NOTE : Specifications are subject to minor change without notice for further improvement. Copyright ©2007 LG Electronics. Inc. All right reserved. Only for training and service purposes -3- LGE Internal Use Only