Lexmark 21Z0300 User Guide - Page 40

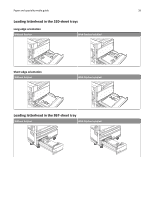

Using transparencies, Using envelopes, Loading letterhead in the 1133, sheet tray

|

UPC - 734646048965

View all Lexmark 21Z0300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 40 highlights

Paper and specialty media guide 40 Loading letterhead in the 1133‑sheet tray Without finisher With finisher installed Using transparencies Print samples on the transparencies being considered for use before buying large quantities. When printing on transparencies: • From MarkVision Professional, Print Properties, or the control panel, set the Paper Type to Transparency. • Feed transparencies from the standard tray or the multipurpose feeder. • Use transparencies designed specifically for laser printers. Check with the manufacturer or vendor to ensure transparencies are able to withstand temperatures up to 230°C (446°F) without melting, discoloring, offsetting, or releasing hazardous emissions. • Use transparencies that are 0.12-0.14 mm (4.8-5.4 mil) in thickness or 161-179 g/m2 in weight. Print quality and durability depend on the transparencies used. • To prevent print quality problems, avoid getting fingerprints on the transparencies. • Before loading transparencies, fan the stack to prevent sheets from sticking together. • We recommend Lexmark part number 12A8240 for letter‑size transparencies. Using envelopes Print samples on the envelopes being considered for use before buying large quantities. When printing on envelopes: • From the control panel, set the Paper Source based on the source in use. From MarkVision Professional, Print Properties, or the control panel, set the Paper Type to Envelope, and select the envelope size. • Use envelopes designed specifically for laser printers. Check with the manufacturer or vendor to ensure the envelopes can withstand temperatures up to 230°C (446°F) without sealing, wrinkling, curling excessively, or releasing hazardous emissions. • For the best performance, use envelopes made from 90 g/m2 (24 lb bond) paper. Use up to 105 g/m2 (28 lb bond) weight for envelopes as long as the cotton content is 25% or less. All‑cotton envelopes must not exceed 90 g/m2 (24 lb bond) weight. • Use only new envelopes. • To optimize performance and minimize jams, do not use envelopes that: - Have excessive curl or twist - Are stuck together or damaged in any way