Lexmark Optra T User's Guide (2 MB) - Page 26

Print material characteristics, Weight, Curl, Smoothness - poor print quality

|

View all Lexmark Optra T manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

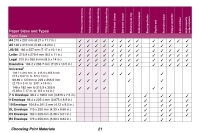

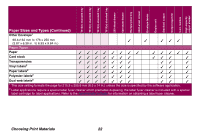

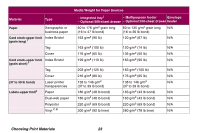

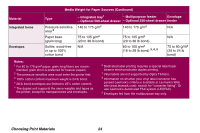

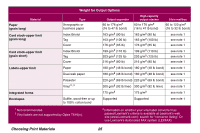

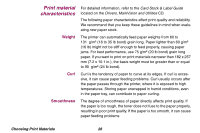

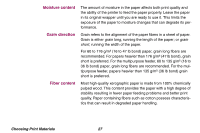

Print material characteristics Weight Curl Smoothness For detailed information, refer to the Card Stock & Label Guide located on the Drivers, MarkVision and Utilities CD. The following paper characteristics affect print quality and reliability. We recommend that you keep these guidelines in mind when evaluating new paper stock. The printer can automatically feed paper weights from 60 to 131 g/m2 (16 to 35 lb bond) grain long. Paper lighter than 60 g/m2 (16 lb) might not be stiff enough to feed properly, causing paper jams. For best performance, use 75 g/m2 (20 lb bond) grain long paper. If you want to print on print materials narrower than 182 x 257 mm (7.2 x 10.1 in.), the basis weight must be greater than or equal to 90 g/m2 (24 lb bond). Curl is the tendency of paper to curve at its edges. If curl is excessive, it can cause paper feeding problems. Curl usually occurs after the paper passes through the printer, where it is exposed to high temperatures. Storing paper unwrapped in humid conditions, even in the paper tray, can contribute to paper curling. The degree of smoothness of paper directly affects print quality. If the paper is too rough, the toner does not fuse to the paper properly, resulting in poor print quality. If the paper is too smooth, it can cause paper feeding problems. Choosing Print Materials 26