Makita EK6101 Operation Manual - Page 27

Troubleshooting, SPECIAL ACCESSORIES

|

View all Makita EK6101 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

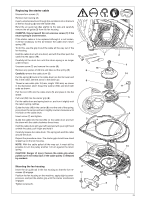

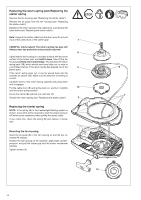

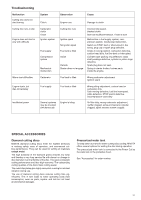

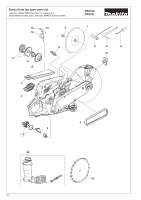

Troubleshooting Malfunction System Observation Cause Cutting disc does not start turning Clutch Engine runs Damage to clutch Cutting disc runs in idle Carburetor, Cutting disc runs clutch V-belt Engine does not start or Ignition system Ignition spark only with difficulty No ignition spark Fuel supply Fuel tank is filled Compression Inside system Outside Mechanical Starter does not engage malfunction Incorrect idle speed, blocked clutch Belt has insufficient tension, V-belt is worn Malfunction in fuel supply system, com- pression system, mechanical malfunction. Switch on STOP, fault or short-circuit in the wiring, plug cap or spark plug defective. Choke in wrong position, carburetor defective, suction head dirty, fuel line bent or interrupted. Cylinder base packing ring defective, radial shaft packings defective, cylinder or piston rings defective Spark plug does not seal. Spring in starter broken, broken parts inside the engine. Warm start difficulties Carburetor Fuel tank is filled Wrong carburetor adjustment. Ignition spark Engine starts, but Fuel supply Fuel tank is filled dies immediately Insufficient power Several systems Engine is idling may be involved simultaneously Wrong idling adjustment, suction head or carburetor dirty. Tank venting defective, fuel line interrupted, cable defective, STOP switch defective. Decompression valve dirty Air filter dirty, wrong carburetor adjustment, muffler clogged, exhaust channel in cylinder clogged, spark arrester screen clogged. SPECIAL ACCESSORIES Diamond cutting discs MAKITA diamond cutting discs meet the highest demands in working safety, ease of operation, and economical cutting performance. They can be used for cutting all materials except metal. The high durability of the diamond grains ensures low wear and thereby a very long service life with almost no change in disc diameter over the lifetime of the disc. This gives consistent cutting performance and thus high economy. The outstanding cutting qualities of the discs make cutting easier. The metal disc plates give highly concentric running for minimal vibration during use. The use of diamond cutting discs reduces cutting time significantly. This in turn leads to lower operating costs (fuel consumption, wear on parts, repairs, and last but not least environmental damage). Pressurized water tank To keep down dust and for better cutting‑disc cooling, MAKITA offers several options for wetting the disc during operation. The pressurized water tank is connected to the Power Cut by the water set on the protective hood. See "Accessories" for order number. 27