Metabo WE 1500-150 RT Operating Instructions - Page 16

Machines with Paddle Switch

|

View all Metabo WE 1500-150 RT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

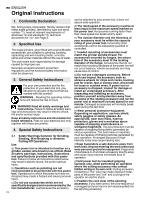

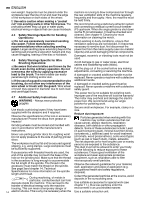

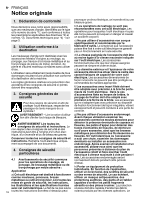

en ENGLISH - Fit the clamping nut (2) on the spindle (4). See illustration on page 2. - (1)Tighten the clamping nut on the clip manually in a clockwise direction. - Flip down the clip (1) again . To release the (tool-free) clamping nut (2) : - Lock the spindle (see chapter 7.1). - Flip up the clip (1) on the clamping nut. - Unscrew the clamping nut (2) , turning it anticlockwise manually . Note: If the clamping nut is very tightly secured (2), you can also use a 2-hole spanner to unscrew it. Avoid inadvertent starts: always switch the tool off when the plug is removed from the mains socket or if there has been a power cut. In continuous operation, the machine continues running if it is forced out of your hands. Therefore, always hold the machine with both hands using the handles provided, stand in a safe position and concentrate. Machines with slide switch: 6 I 0 7.4 Securing/releasing the clamping nut (depending on features) Securing the clamping nut (12): The 2 sides of the clamping nut are different. Screw the clamping nut onto the spindle as follows: See page 2, illustration B. - A) For thin grinding wheels: The edge of the clamping nut (12) faces upwards so that the thin grinding wheel can be attached securely. B) For thick grinding wheels: The edge of the clamping nut (12) faces downwards so that the clamping nut can be attached securely to the spindle. - Lock the spindle. Turn the clamping nut (12) clockwise using the 2-hole spanner (13) to secure. Releasing the clamping nut: - Lock the spindle (see chapter 7.1). Turn the clamping nut (12) anticlockwise using the 2-hole spanner (13) to unscrew. Switching on: Push the slide switch (6) forward. For continuous activation, now tilt downwards until it engages. Switching off: Press the rear end of the slide switch (6) and release. Machines with Paddle Switch (with dead man function): 89 Switching the angle grinder ON just for a moment: Switching on: Press in the lock (8) and then press the trigger switch (9). Let go of the lock (8). Switching off: Release the trigger switch (9). 8. Use 8.1 Adjusting the speed (depending on features) Set the recommended speed at the thumbwheel. (7) (small number = low speed; large number = high speed) Cutting disc, roughing disc, cup wheel and diamond cutting disc: high speed Brush: medium speed Sanding plate: low to medium speed Note: We recommend using our angle polisher for polishing work. 8.2 Switching On and Off Always guide the machine with both hands. Switch on first, then guide the accessory towards the workpiece. The machine must not be allowed to draw in additional dust and shavings. When switching the machine on and off, keep it away from dust deposits. After switching off the machine, only place it down when the motor has come to a standstill. 16 Continuous operation (depends on machine features): Switching on: Press in the lock (8) and hold in place. Press and hold the trigger switch (9). The machine is now switched on. Now press in the lock (8) a second time to lock the trigger switch (9) in position (continuous operation). Switching off: Press and release the trigger switch (9). 8.3 Working instructions Grinding: Press down the machine evenly on the surface and move back and forth so that the surface of the workpiece does not become too hot. Roughing: position the machine at an angle of 30° - 40° for the best working results. Separating: Always work against the run of the disc (see illustration). Otherwise there is the danger of the machine kicking back from the cut out of control. Guide the machine evenly at a speed suitable for the material being processed. Do not tilt, apply excessive force or sway from side to side.