Pfaff 145 Owner's Manual - Page 13

Changing, Alternating, Pressers - timing

|

View all Pfaff 145 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

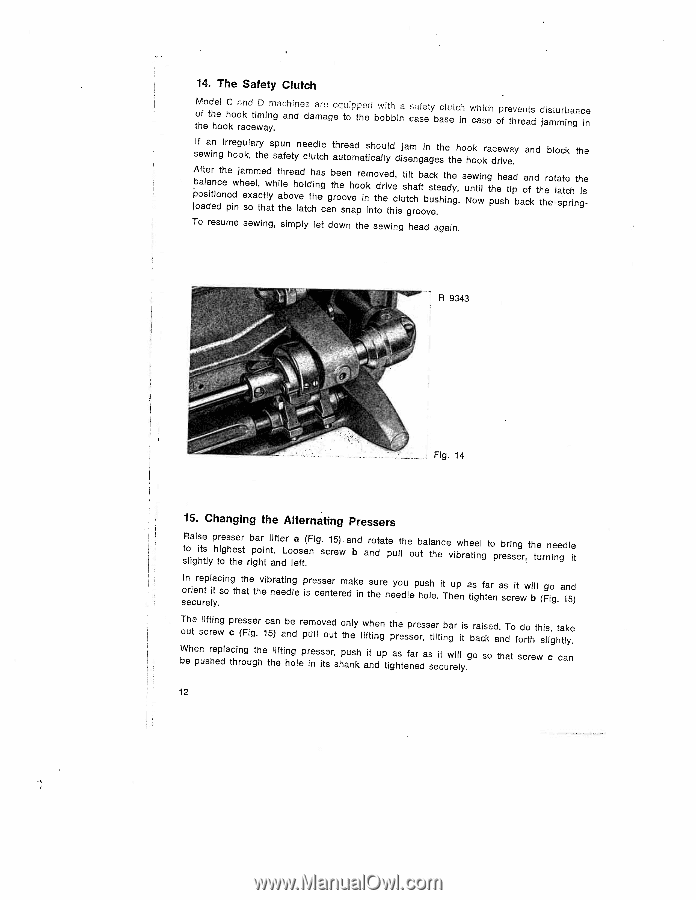

14. The Safety Clutch Model C and D machinee are equipped with a of the hook timing and damage to the bobbin the hook raceway. safety clutch case base in which case prevents of thread disturbance jamming in If an irregulary spun needle sewing hook, the safety clutch thread should jam in the hook raceway automatically disengages the hook drive. and block the lpAbooafatsldeairtenidoctnehpeeidwnjhaesemoxeaml,cthetlwdaythtiathlhbereoehvalodeatlcdthhihnaegscagnbtrhoeeeosnnvhaeoproeinkminottdohvreeitvdhec,islutsithglctrahofbtobavcsuetks.ehatidhnyeg,. sewing head and rotate the until the tip of the latch is Now push back the spring- To resume sewing, simply let down the sewing head again. R 9343 Fig. 14 15. Changing the Alternating Pressers Raise presser to its highest slightly to the bar lifter a (Fig. 15) point. Loosen screw right and left. and b rotate the balance wheel and pull out the vibrating to bring presser, the needle turning it In replacing the vibrating orient it so that the needle securely. presser make is centered in sure you push the needle hole. it up Then as far as it will tighten screw b go and (Fig. 15) The lifting out screw presser c (Fig. can be 15) and removed pull out only when the lifting the presser bar is raised. To do this, take presser, tilting it back and forth slightly. When replacing the lifting presser, push be pushed through the hole in its shank it up as far as it will go and tightened securely. so that screw c can 12