Poulan 1990-10 User Manual - Page 19

Filter, Storage

|

View all Poulan 1990-10 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

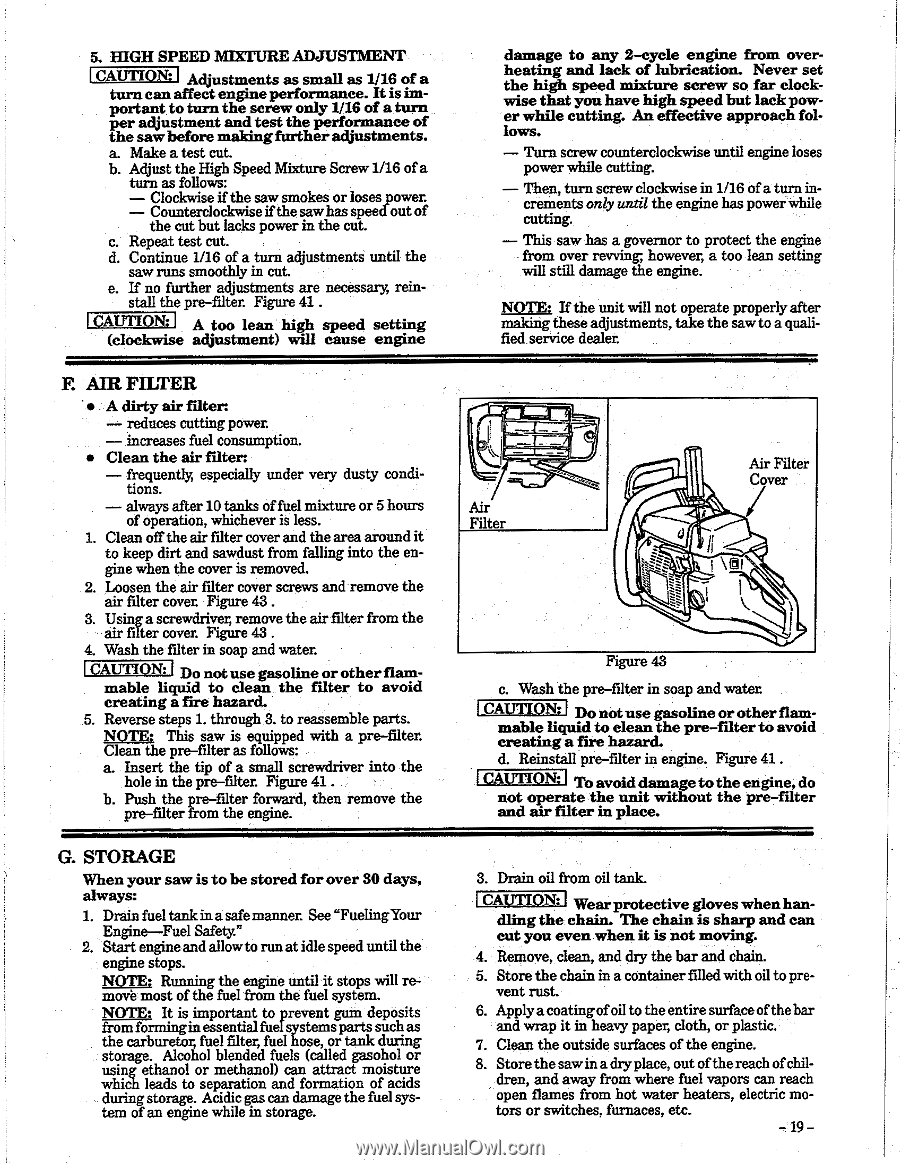

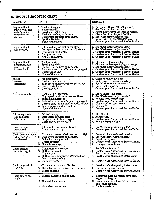

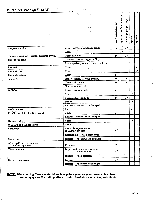

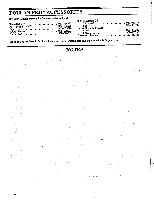

5. HIGH SPEED MIXTURE ADJUSTMENT CAUTION: Adjustments as small as 1/16 of a turn can affect engine performance. It is hnportant to turn the screw only 1/16 of a turn per adjustment and test the performance of the saw before making further adjustments. a. Make a test cut. b. Adjust the High Speed Mixture Screw1/16 of a turn as follows: - Clockwise if the saw smokes or loses power. - Counterclockwise if the sawhas speed out of the cut but lacks power in the cut. c. Repeat test cut. d. Continue 1/16 of a turn adjustments until the saw runs smoothly in cut. e. If no further adjustments are necessary, reinstall the pre-filter. Figure 41 . CAUTION: A too lean high speed setting (clockwise adjustment) will cause engine E AIR. FILTER • • A dirty air filter: - reduces cutting power. - increases fuel consumption. • Clean the air filter: - frequently, especially under very dusty condi- tions. - always after 10 tanks of fuel mixture or 5 hours of operation, whichever is less. 1. Clean off the air filter cover and the area around it to keep dirt and sawdust from falling into the engine when the cover is removed. 2. Loosen the air filter cover screws and remove the air filter covet Figure 43 . 3. Usinga screwdriver, remove the air filter from the air filter cover. Figure 43 . 4. Wash the filter in soap and water. CAUTION: Do not use gasoline or other flammable liquid to clean the filter to avoid creating a fire hazard. 5. Reverse steps 1. through 3. to reassemble parts. NOTE: This saw is equipped with a pre-filter. Clean the pre-filter as follows: a. Insert the tip of a small screwdriver into the hole in the pre-filter. Figure 41. b. Push the pre-filter forward, then remove the pre-filter from the engine. G. STORAGE When your saw is to be stored for over 30 days, always: 1. Drain fuel tank in a safe manner. See "FuelingYour Engine-Fuel Safety." 2. Start engine and allowto runat idle speed until the engine stops. NOTE: Running the engine until it stops will remove most of the fuel from the fuel system. NOTE: It is important to prevent gum deposits from formingin essentialfuelsystems parts suchas the carburetor, fuel filter, fuel hose, or tank during storage. Alcohol blended fuels (called gasohol or using ethanol or methanol) can attract moisture which leads to separation and formation of acids during storage. Acidic gas can damage the fuel system of an engine while in storage. damage to any 2-cycle engine from overheating and lack of lubrication. Never set the high speed mixture screw so far clockwise that you have high speed but lack power while cutting. An effective approach follows. - Turn screw counterclockwise until engine loses power while cutting. - Then, turn screw clockwise in 1/16 of a turn increments only until the engine has powerwhile cutting. - This saw has a governor to protect the engine from over revving; however, a too lean setting will still damage the engine. NOTE: If the unitwill not operate properly after making these adjustments, take the saw to a qualified service dealer. Air Filter Air Filter Cover a 11 Figure 43 c. Wash the pre-filter in soap and water. CAUTION: Do not use gasoline or other flam- mable liquid to clean the pre-filter to avoid creating a fire hazard. d. Reinstall pre-filter in engine. Figure 41 . CAUTION: To avoid damage tothe engine, do not operate the unit without the pre-filter and air filter in place. 3. Drain oil from oil tank. CAUTION: Wear protective gloves when handling the chain. The chain is sharp and can cut you even when it is not moving. 4. Remove, clean, and dry the bar and chain. 5. Store the chain in a container filled with oil to pre- vent rust. 6. Applya coatingof oil to the entire surfaceof the bar and wrap it in heavy paper, cloth, or plastic. 7. Clean the outside surfaces of the engine. 8. Store the saw in a dry place, out of the reach of chil- dren, and away from where fuel vapors can reach open flames from hot water heaters, electric motors or switches, furnaces, etc. -!19 -