Poulan PO1538D User Manual - Page 17

Clean Air Screen, Engine Cooling Fins See Fig. 12, Air Filter See Fig. 13

|

View all Poulan PO1538D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

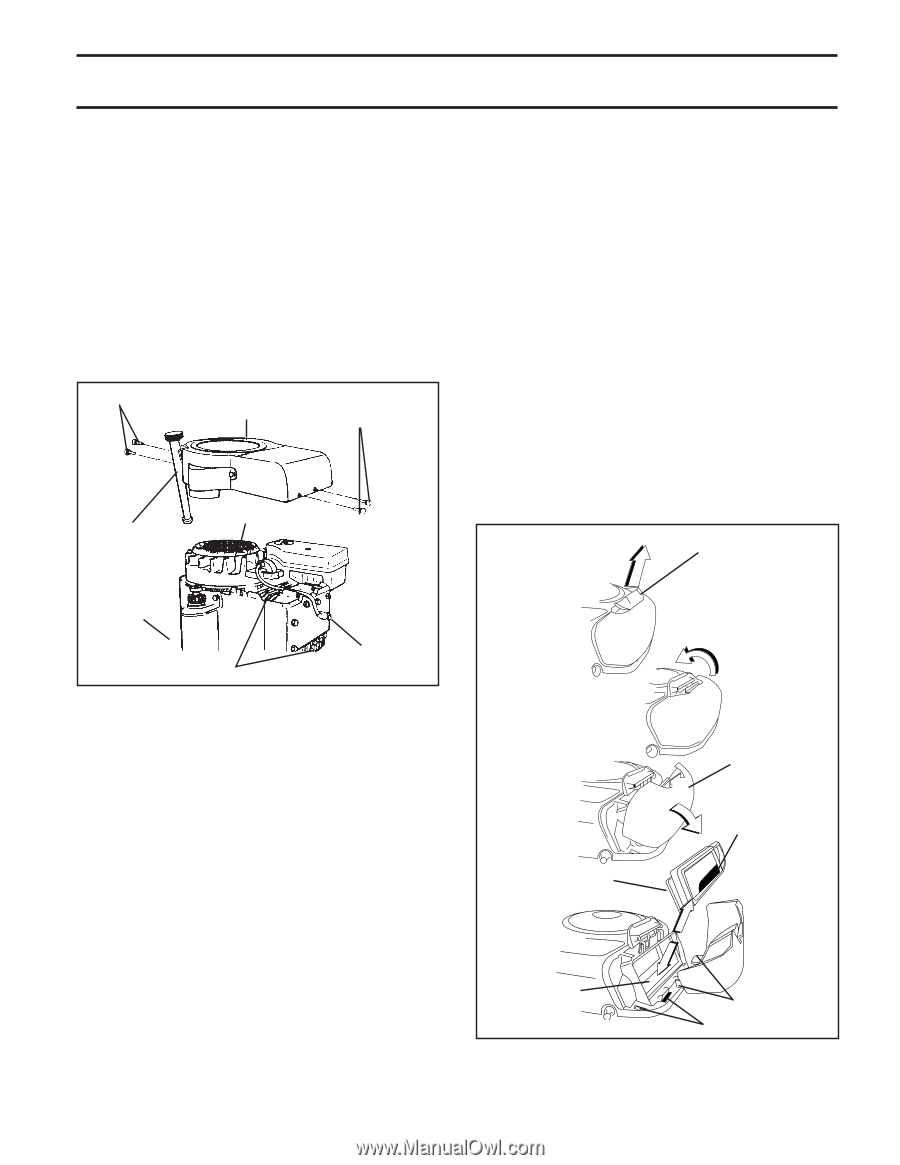

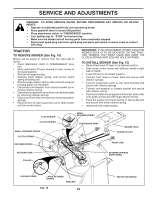

MAINTENANCE CLEAN AIR SCREEN Air screen must be kept free of dirt and chaff to prevent engine damage from overheating. Clean with a wire brush or compressed air to remove dirt and stubborn dried gum fibers. ENGINE COOLING FINS (See Fig. 12) Remove any dust, dirt or oil from engine cooling fins to prevent engine damage from overheating. • Remove screws from blower housing and lift housing and dipstick tube assembly off engine. • Cover oil fill opening to prevent entry of dirt. • Use compressed air or stiff bristle brush to thoroughly clean engine cooling fins. • To reassemble, reverse above procedure. SCREWS BLOWER HOUSING SCREWS OIL FILL TUBE ASSEMBLY AIR SCREEN AIR FILTER (See Fig. 13) Your engine will not run properly using a dirty air filter. Replace pre-cleaner after every 25 hours of operation or every season. Service paper cartridge every 100 hours of operation or every season, whichever occurs first. Service air cleaner more often under dusty conditions. • Pull up on air filter cover handle and rotate towards engine. • Remove cover. • Carefully remove air filter cartridge and pre-cleaner from base. • Clean base carefully to prevent debris from falling into carburetor. NOTE: If very dirty or damaged, replace cartridge. • Place new pre-cleaner and cartridge firmly in base. • Align tabs on cover with slots in blower housing and replace cover. • Hook handle on cover and push down on handle to close. IMPORTANT: Petroleum solvents, such as kerosene, are not to be used to clean the cartridge. They may cause deterioration of the cartridge. Do not oil cartridge. Do not use pressurized air to clean cartridge. HANDLE OIL FILL OPENING ENGINE COOLING FINS FIG. 12 SPARK PLUG COVER PRE-CLEANER CARTRIDGE BASE FIG. 13 TABS SLOTS 17