Ryobi AP1301 English Manual - Page 14

Operation - replacement blades

|

View all Ryobi AP1301 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

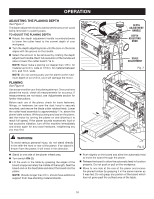

OPERATION WARNING: Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a second is sufficient to inflict serious injury. WARNING: Always wear safety goggles or safety glasses with side shields when operating power tools. Failure to do so could result in objects being thrown into your eyes resulting in possible serious injury. WARNING: Do not use any attachments or accessories not recommended by the manufacturer of this tool. The use of attachments or accessories not recommended can result in serious personal injury. WARNING: The use of this planer on materials not recommended may damage the planer and may cause serious personal injury. WARNING: Never plane a workpiece with loose knots or foreign objects. Do not plane workpieces that are severely bowed, twisted, or knotted. Cutter blades can dull, chip, or break, causing possible serious personal injury. WARNING: Do not force feed the workpiece through the machine. Let the planer apply the proper feed rate. APPLICATIONS You may use this tool for the purpose listed below: Planing the surface of solid wood and wood products THICKNESS PLANING Thickness planing sizes the workpiece to a desired thickness while creating a smooth, level surface. The thickness of each cut will depend on the type of wood (hardwood versus softwood), width of workpiece, straightness, dryness, and grain composition. Whenever working with a new type of wood, make thin test cuts on a scrap piece of wood first to determine potential problems with the workpiece. PLANING TIPS Thickness planers work best if at least one side of the workpiece has a flat surface. When both sides of a workpiece are rough, use a surface planer or jointer first to define the initial flat surface. Plane one side of the workpiece, then flip the workpiece and plane the surface of the reverse side. Always plane both sides of a workpiece to reach the desired thickness. This will leave the workpiece with uniform moisture to prevent warping during the drying process. When one end of the workpiece is thicker than the opposite end by more than 1/8 in., make several cuts with the planer starting with light planing cuts first. Remember, light cuts create a finer finish than heavier cuts. Do not plane a workpiece less than 3/16 in. thick. Do not plane a workpiece less than 3/4 in. wide. Do not plane a workpiece shorter than 14 in. long as this will cause kickback. Do not plane more than one workpiece at a time. Do not lower the cutter head assembly lower than 3/16 in. � Do not use the planer set at the maximum depth of cut (1/8 in.) and at full width of cut (13 in.). Continuous use at maximum cutting capacity will damage the motor. Worn cutter blades will affect cutting accuracy. Planing with dull or nicked cutter blades may produce ridges or rough workpiece surfaces. Gum and pitch on the cutter blades will cause them to wear prematurely. Using a gum and pitch remover to keep the cutter blades clean will prolong their wear. Refer to the Maintenance section of this operator's manual for instructions on how to remove and replace or turn the cutter blades. NOTE: Cutter blades are double-edged and can be turned once to the opposite, unused edge before replacement is required. Cutter blades must ALWAYS be replaced as a set. 14