Ryobi DP121L English Manual - Page 17

Installing/using The Spindle Lock, Lever, Checking/adjusting Laser Alignment, Warning - chuck

|

View all Ryobi DP121L manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

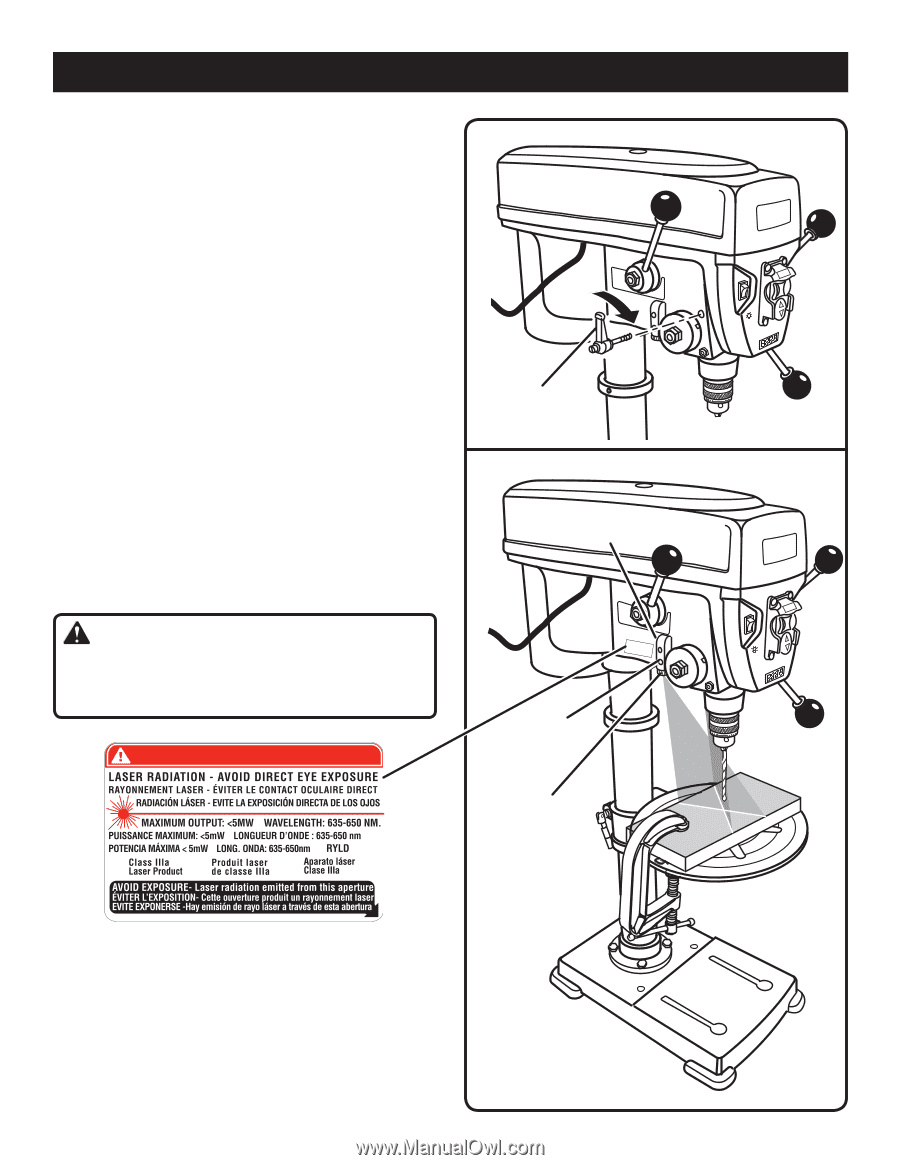

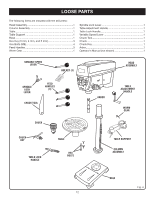

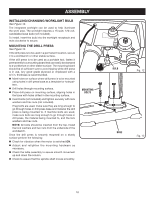

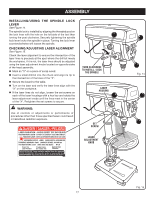

assembly installing/using the spindle lock lever See Figure 14. The spindle lock is installed by aligning the threaded post on the lock lever with the hole on the left side of the tool then turning the post clockwise. Securely tightening the spindle lock lever locks the spindle in place. Turning the lock lever counterclockwise will loosen the spindle. CHECKING/adjusting Laser Alignment See Figure 15. Check the laser alignment to ensure the intersection of the laser lines is precisely at the spot where the drill bit meets the workpiece. If it is not, the laser lines should be adjusted using the laser adjustment knobs located on opposite sides of the head assembly. Mark an "X" on a piece of scrap wood. Insert a small drill bit into the chuck and align its tip to the intersection of the lines of the "X". Secure the board to the table. Turn on the laser and verify the laser lines align with the "X" on the workpiece. If the laser lines do not align, loosen the set screws on each of the laser housings with a hex key and rotate the laser adjustment knobs until the lines meet in the center of the "X". Retighten the set screws to secure. WARNING: Use of controls or adjustments or performance of procedures other than those specified herein could result in hazardous radiation exposure. DANGER / DANGER / PELIGRO DANGER / DANGER / PELIGRO turn clockwise to install / lock the spindle laser housing set screw LASER ADJUSTMENT knob Fig. 14 Fig. 15 17