Sharp 21FL94 Service Manual - Page 22

X-ray Protection Operating Confirmation

|

View all Sharp 21FL94 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

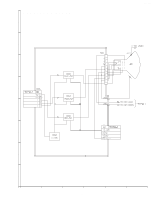

21FL94 22 ADJUSTMENT ITEM ADJUSTMENT POSITION V03 SUB-COLOR STEP RANGE 0-127 CONTROL I2C BUS CONTROL PRE-ADJUST REQUIREMENT OPTION SET UP, BUS SET UP, VCO ADJ, RF-AGC, SUB-PICT, SUB-TNT CONTENT US 10 CH HALF COLOR BAR PATTERN INPUT CONDITION OUTPUT 220V R-AMP TR BASE (TP851) CONFIRRM WITH OSCILLOSCOPE 1) SET THE V03 BUS DATA TO GET A WAVEFORM AS BELOW 2) THIS WAVEFORM SHOWS THAT THE 75% WHITE & RED PORTIONS OF COLOR BAR BEAT AT THE SAME LEVEL *PLEASE TAKE NOTE THAT SERVICE DATA F60 MUST SET TO +10 Cy G ADJUSTMENT PROCEDURE 100% WHITE WY Mg R B [CHECKING CONFIRMATION] HISTORY SYMBOL REVISED CONTENT, OF REVISION 22-1 ADJUSTMENT ITEM ADJUSTMENT POSITION X-RAY PROTECTION OPERATING CONFIRMATION - STEP RANGE - CONTROL - PRE-ADJUST REQUIREMENT AFTER ALL ADJUSTMENT FINISHED. CONTENT US 4 CH LION HEAD (MONOSCOPE PATTERN) INPUT CONDITION AC 220V, RF INPUT OUTPUT CONFIRMATION BY THE CRT SET THE USER CONTROL TO SHIPMENT POSITION. [VOLTAGE CONFIRMATION] CHECK THE VOLTAGE OF P603 PIN 3 AS SPECIFIED BELOW. [OPERATION CONFIRMATION] SUPPLY THE DC VOLTAGE TO P603 PIN 3 AND MAKE SURE THE PROTECTOR IS FUNCTIONED. HORIZONTAL OSCILATION STOP AND PICTURE DISAPPEAR. ADJUSTMENT [RECOVER INFORMATION] PROCEDURE PULL OUT THE AC CORD. [CAUTION] FROM THE RECOVER CONFIRMATION MENTIONED ABOVE, THE AC CODE MUST BE PULLED OUT AT LEAST 4 SECOND BEFORE PLUGGING IN AGAIN.(IN ORDER TO MAKE SURE THE µ-COM HAS BEEN RESET.) [VOLTAGE CONFIRMATION] TP VOLTAGE 26± 1.1V DC OPERATION VOLTAGE 27V HISTORY SYMBOL REVISED CONTENT, OF REVISION 22-2